Technology theme: High-temperature superconducting wire joint technologies leading to innovative reduction of energy loss

Superconductivity technologies are used in NMR and MRIs, as well as in superconducting magnetic levitation railways. However, low-temperature superconductivity materials, which are commonly used in society, require expensive liquid helium as coolant. This represents an obstacle to the popularization of superconductivity technologies. Considering this, liquid nitrogen, which has a relatively low cost, and high-temperature superconductivity materials, which can form higher-level magnetic fields than low-temperature superconductivity materials, would be more effective for achieving full-scale implementation in society. However, because high-temperature superconductivity wire materials can only be manufactured in lengths of a few hundred meters, the technology that can join wires keeping superconductivity or extremely low resistance is required to achieve their practical application. Such joining technology, if established, would bring the creation of efficient, high magnetic-field coil and long-distance, direct-power transmission close to realization - qualities that are expected of superconductive materials.

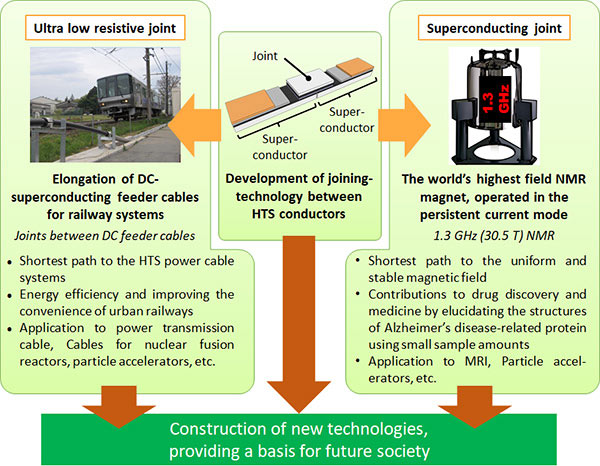

Social implementation of super-high field NMRs and DC superconducting cables for railway systems, through advancement of joint-technology between hightemperature superconducting wires

| R&D Period | 2017.11- |

|---|---|

| Grant Number | JPMJMI17A2 |

| Project Summary | Summary |

Summary:

Low temperature superconductors require liquid helium, while only generating a magnetic field less than 24 T. For full-fledged commercialization, high temperature superconducting (HTS) conductors are preferred as they are cooled by liquid nitrogen, generating a much higher magnetic field. However, the drawback of the HTS conductor is its availability only in short lengths of a single conductor, such as 500 m. This necessitates many joints being installed in the superconducting apparatus, resulting in difficult manufacturing process and a complicated operatingprocedure. Hence, we have commenced a new project, comprising two R&D items: (a) development of superconducting-joints (10-13 Ω)between HTS conductors, which are installed in the world's highest field persistent current mode 1.3 GHz (30.5 T) NMR; the joining performance is evaluated based on NMR spectra: (b) development of ultra-low resistive joints(10-7~10-8 Ω)between DC superconducting feeder cables, > 100 mm in diameter, for railway systems, which are evaluated by the operational test of a train in the Railway Technical Research Institute.

R&D Team

RIKEN, Aoyama-Gakuin University, National Institute for Materials Science, TEP, Sumitomo Electric, Japan Fine Ceramics Center, Kyushu University, Japan Superconductor Technology, Okayama University, Institute of Science Tokyo, JEOL RESONANCE, Railway Technical Research Institute, Kyushu Institute of Technology, Tohoku University, Muroran Institute of Technology

Project Website

https://www.jst-mirai-sc.riken.jp

|

Affiliation and job title should automatically appear from the information that a researcher registered with researchmap.

Data may be outdated or undocumented. When there is not a connection via the internet, data are not displayed. |