About Research Domains

- JST HOME

- SM4I HOME

- Research Domains Top

- MI Top

- Development of MI System

[Main Text]

About Research Domains

The Center of Excellence at The University of Tokyo and National Institute for Materials Science (NIMS)

Development of MI System

(D61・D62・D63・D64)

Concept and Approach

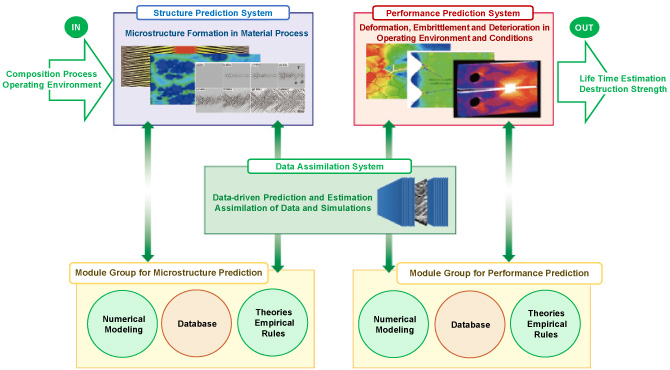

We are developing system for predicting the performance and life-time of structures made of combinations of various materials and processes by integrating theories, empirical rules, computational simulations, databases and other tools. We aim to realize systems that help greatly shorten the material development time, develop materials efficiently, reduce costs, select materials, manufacture, optimize utilization manufacturing process, predict the reliability of structures, improve diagnosis and maintenance, and also help establish centers of materials research and development and centers of personnel training, and build up international network.

Research and Development

Development of Microstructure Prediction System

Microstructure of materials changes significantly due to the thermal cycles during welding, often resulting in the deterioration of mechanical properties. Precisely predicting the microstructural change in this heat-affected zone (HAZ) is therefore important for the safety of welded structures. Among the numerical simulation techniques proposed so far are the experimental and theoretical equations such as the estimation equation for HAZ hardness, the carbon equivalent equation and the evaluation equation of hardenability, as well as the computational simulation technologies such as phase-field models, cellular automata method, and Monte Carlo method. We reevaluate these conventional theoretical equations and numerical simulation techniques, while developing new modules for improving the prediction accuracy of numerical modeling. Moreover, the microstructure during multiple heat cycles, for which an experimental equation has not yet been adequately established, and the microstructure of welded metal will also be modeled by prediction equations through previously accumulated data.

Unit Structure and Role

Development of Microstructure Prediction System and Module Group

for Materials / Components

- The University of Tokyo

- Microstructure Prediction System

- Analytic Engines based on Phase-Field Method

- Microstructure Formation Data

- Microstructure Prediction Modules based on theory and empirical rules

- National Institute for Materials Science (NIMS)

- Combined System between the Phase-Field Models and CALPHAD Method

- Hokkaido University

- Modules for Predicting Microstructure Formation by Solidification

- Tokyo University of Agriculture and Technology

- Diffusive Phase Transformation Modules

- Nagoya University

- Displacive Phase Transformation Modules

- JFE Steel, Kobe Steel, IHI, UACJ

- Development and Verification of Modules for Predicting Welded Structures

Development of Performance Prediction System

Prediction of Fatigue Strength, Creep Strength, Hydrogen Embrittlement and Brittle Fracture

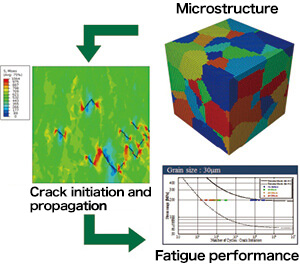

The system for time-dependent performance prediction of structural materials, such as fatigue strength, creep strength, hydrogen embrittlement and brittle fracture, is developed based on microstructure information which is obtained by the microstructure prediction system. This performance prediction system consists of two modules groups – one is the simulation module group based on theoretical physical model and forward analysis, and the other is the database module group utilizing accumulated performance data. We verify the effectiveness of the performance prediction system by verifying to evaluate the validity of the predicted performance. We also develop a module that predicts time-dependent performance under certain conditions of use from materials, welding conditions and welding structure, even if microstructural information is not always available.

Unit Structure and Role

Development of Performance Prediction system and Module Group for Materials / Composites / Structure

- The University of Tokyo

- Performance Prediction System

- Computational Modules for Fatigue Performance with High Accuracy

- Computational Modules for Brittle Fracture

- High Speed Computational Modules for Fast Fatigue Performance

- Performance Prediction Database Tools

- National Institute for Materials Science (NIMS)

- Computational Modules for Creep Performance

- Fatigue Database Modules

- Teikyo University

- Computational Modules for Hydrogen Embrittlement

- JFE Steel, Kobe Steel, IHI, UACJ

- Development and Verification of Performance Prediction Modules

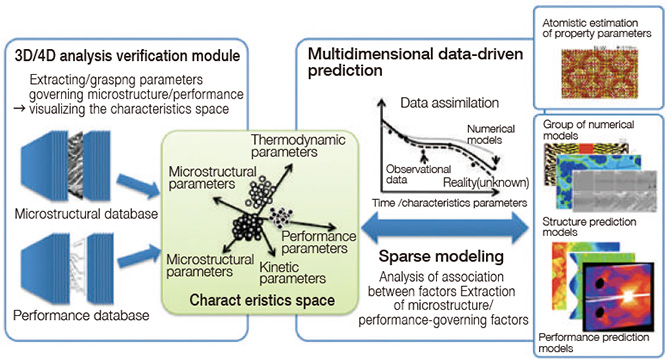

Development of Data Assimilation System

We are attempting to establish a method for grasping a characteristics space consisting of descriptors that determine performance and microstructure by applying information theory and statistical mechanics. Specifically, we are trying to apply sparse modeling method which extracts useful finding from various descriptors/ models based on the database, and data assimilation method, which estimates various parameters and their uncertainties based on the database, to the prediction modules developed in microstructure prediction system and performance prediction system. At the same time, we are developing a module for automatically extracting geometrical factors designed to describe the microstructure of materials, and analyzing the correlation between parameters and various input conditions used in various prediction modules.

Unit Structure and Role

Development of Data Assimilation System for supporting microstructure / Performance Prediction System by using data processing analysis

- The University of Tokyo

- Data Assimilation System

- Multidimensional data-driven prediction techniques based on statistical mechanics

- Data Assimilation of Materials Mechanical Properties

- Probabilistic Performance Prediction Techniques

- National Institute for Materials Science (NIMS)

- Multidimensional data-driven prediction techniques based on information theory and statistical mechanics

- Nagoya University

- Microstructure Database

- Establishment of property prediction techniques based on information theory and statistical mechanics

- Optimization of parameters for the phase-field models based on data assimilation

- Riken

- Technique for grasping a material characteristic space

- Microstructure Database

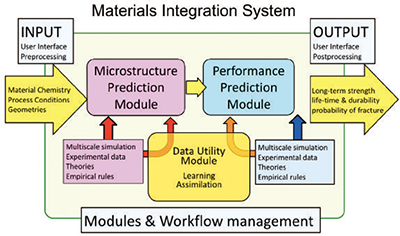

Development of Materials Integration System

We are developing an integrated R&D support system to accelerate material development. We are aiming to realize a material integration system that connects and integrates various analysis modules for microstructure prediction and performance prediction. This system can predict long-term material performance such fatigue and creep life by giving material composition and process condition as input. Encompassing abundant structural materials database, it is possible to estimate the physical properties and analytical parameters required by each analysis module by machine learning. In the future, we will aim to realize a system that can incorporate data and analytical modules provided by users, and do efficient material search according to the needs of each user.

Unit Structure and Role

Development of the basic structure and external interface of Materials Integration System that links and controls each system

- National Institute for Materials Science (NIMS)

- Materials Integration System

- Establishment of a base for integrating various data and modules

- The University of Tokyo

- Implementation of performance prediction database tools

- Toyo University

- Data and knowledge representation for materials

- Aoyama Gakuin University

- Web user interface for MI System

- Nagoya University

- Visualization System

List of R&D Projects and Units

| Category | No. | R&D Project | Research Unit | Unit Leader |

|---|---|---|---|---|

| Metal MI | D61 | Materials Integration | Development of Microstructure Prediction System | ◎☆Toshihiko Koseki (UTokyo) |

| D62 | Development of Performance Prediction System | Manabu Enoki (UTokyo) | ||

| D63 | Development of a System for Data Assimilation and Machine Learning | Junya Inoue (UTokyo) | ||

| D64 | Development of Materials Integration System | ☆Makoto Watanabe (NIMS) | ||

| D65 | Development of Simulation Technique for Performance Assurance of Weld Joints | ☆Akio Hirose(Osaka U.) | ||

| D67 | Fundamental Research Focusing on Interface for overcoming Unsolved issues in Structural Materials | ☆Kaneaki Tsuzaki (Kyushu U.) | ||

| Innovative Measurement | D66 | Innovative Measurement and Analysis for Structural Materials | ☆Masataka Ohkubo (AIST) | |

| Ceramics Coating MI | D68 | Development of Simulation for Mass Transfer at High Temperature and Time Dependent Behavior of Microstructure | Hideaki Matsubara (Tohoku U.) | |

| D69 | Development of Computational Tools to Predict Time Dependent Phenomena in Structural Materials | Tetsuo Mohri (Tohoku U.) | ||

| D73 | Establishment of Domestic Technology Base for Computational Thermodynamics for Development of Advanced Structural Materials | Kazuhisa Shobu (AIST) | ||

| Engineering Polymers MI | D70 | Development of Prediction Tools for Long-term Properties of High Performance Engineering Plastics | Takashi Kuriyama (Yamagata U.) | |

| D71 | Development of Practical Optimal Design and Comprehensive Evaluation Support Tool for Advanced Structural Polymer Materials | Shin-etsu Fujimoto (Nippon Steel & Sumikin Chemical) | ||

| D72 | Mathematical Approach Toward Materials Integration and its Applications | Yasumasa Nishiura (Tohoku U.) | ||

| D74 | Performance Prediction for Polymers by Nonlinear Analysis | Kazuyuki Shizawa (Keio U.) | ||

| D75 | Atomic / Molecular-level Approaches for Designing Novel Polymeric Materials | Takefumi Yamashita (UTokyo) | ||

◎:Co-Director of Research Domain ☆:Co-Manager