About Research Domains

- JST HOME

- SM4I HOME

- Research Domains Top

- Polymers and CFRP

[Main Text]

About Research Domains

The Center of Excellence at the University of Tokyo and JAXA

Innovative CFRP for Aircraft

(A01・A02・A03・A04・A11)

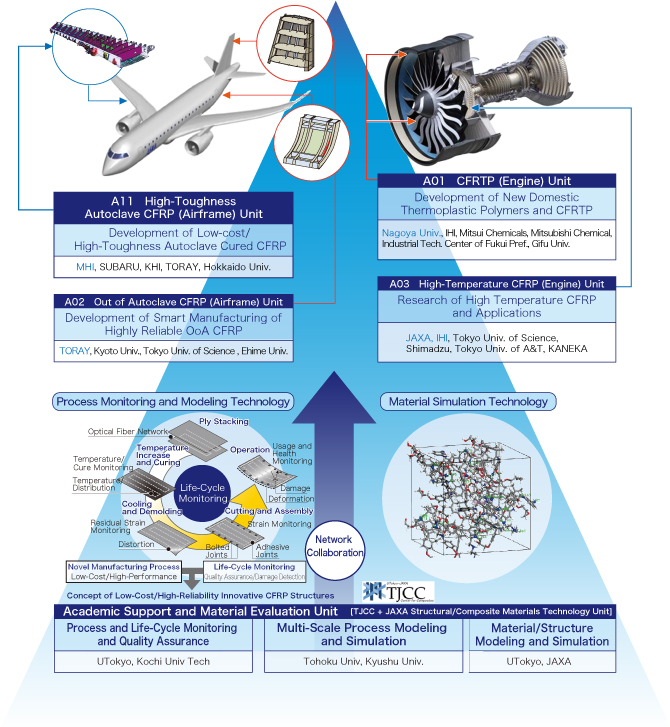

Concept and Approach

The main purpose of this project is to develop high-rate production aircraft PMC products and quality assurance technology for next-generation CFRP aircraft structures. This project consists of five research units, (1) OoA CFRP (Airframe) Unit, (2) Low-Cost/High-Toughness Autoclave CFRP (Airframe) Unit, (3) CFRTP (Engine) Unit, (4) High-Temperature CFRP (Engine) Unit, and (5) Academic Support and Material Evaluation Unit. A strong collaboration among fiber/matrix industries, aircraft manufacturing industries, universities and national institutes is key for the success of this program.

Research and Development

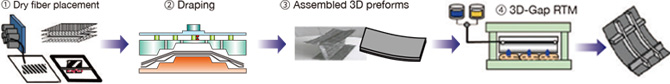

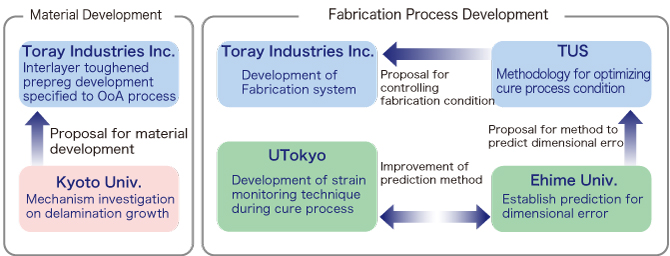

Development of Smart Manufacturing of Highly Reliable OoA CFRPOoA CFRP (Airframe) Unit

Development of Smart Manufacturing of Highly Reliable OoA CFRP

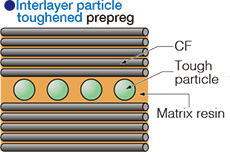

- Innovative molding technology for aircraft wing structure based on active thermal control system with a novel interlayer toughened prepreg specified to Out-of-Autoclave process

- Demonstration of door panel by 3D-Gap RTM technology

- Establishment of process monitoring techniques (resin-flow and resin-curing reaction processes)

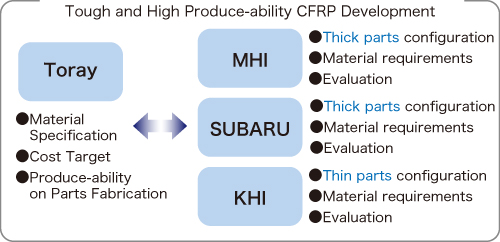

Development of High-Toughness Autoclave Cured CFRPLow-Cost /High-Toughness Autoclave CFRP (Airframe) Unit

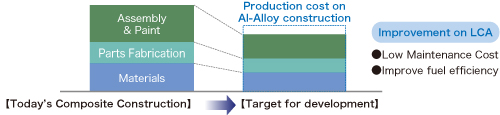

Development of low cost, high toughness Autoclave cured CFRP for aircraft main structure

- All Japan Standard CFRP for primary structures (wing and fuselage) adding favorable attributes such as low cost and tough material (50% tougher than benchmark)

- All Japan collaboration for future airplane development:

Material Manufacturer – Toray, Airframe Manufacturers – MHI, SUBARU, KHI - Optimization of composite stacking sequence and structural optimization (Hokkaido University)

Started in 2016

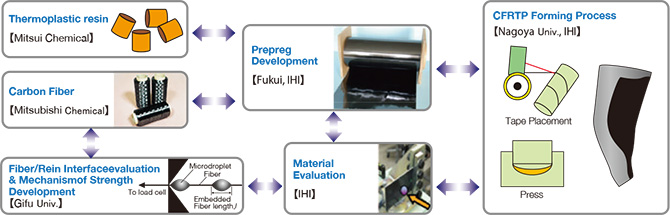

Development of New Domestic Thermoplastic Polymers and CFRTPCFRTP (Engine) Unit

Development of Impact Resistant Thermoplastic Resin / CFRTP Prepreg and Forming Process Technology

- To further reduce the weight of aviation engine large structures, SIP development will achieve impact and heat resistant low-cost domestic thermoplastic resin prepreg and CFRTP, as well as a high molding technology.

Development of High Temperature CFRP and Aeroengine Application TechnologyHeat Temperature CFRP (Engine) Unit

Development of High Temperature CFRP and Aeroengine Application Technology

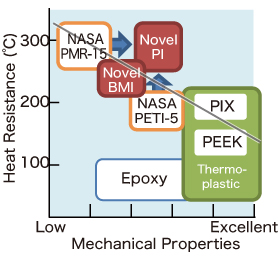

- Research and development of the material, processing and evaluation technologies for applying high-temperature polymer matrix composites such polyimide and bismaleimide composites to turbo-fan engine parts (target operating temperatures are 200 to 250 ℃).

- Material Technology

- R&D of micromechanical test method and viscoelasticity at elevated temperatures, and thermal analysis for processing technology.

- TUS, Shimadzu, KANEKA

- Processing Technology

- Establishment of a fundamental fabrication process to produce flat panels of high temperature composites and construction of database.

- IHI, JAXA, TUAT

- High Temperature Evaluation Technology

- Establishment of tensile, compressive and shear test methods at elevated temperatures.

- JAXA, TUAT, Shimadzu, IHI

Development of Process Monitoring, Modeling and Quality Assurance TechnologyAcademic Support and Evaluation Unit

Development of Process Monitoring, Modeling and Quality Assurance Technology

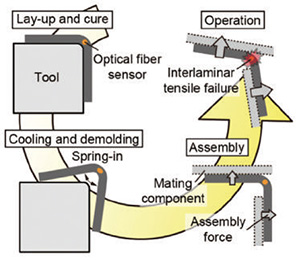

- Development of optical fiber based in-process material quality monitoring and quality assurance technology as a basic academic technology. Establishment of manufacturing process foundation to avoid trials and errors.

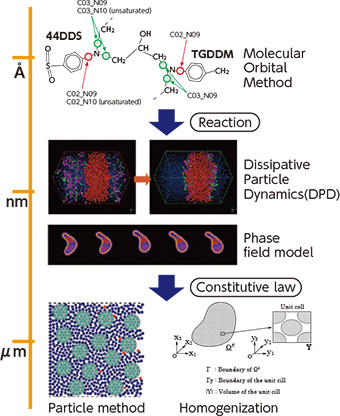

- Development of Multi-Scale Simulation Methodology in manufacturing process and structural characterization.

- Process and Life-Cycle Monitoring

and Quality Assurance - UTokyo, Kochi Univ. Tech

- Multi-Scale Process Modeling and Simulation

- Tohoku Univ., Kyushu Univ.

- Material/Structure

Modeling and Simulation - UTokyo, JAXA

- Development of In-Process Residual Strain Measurement and High Precision Simulation Methodology to provide efficient and optimum processing conditions for novel CFRP materials.

Development of Carbon Fiber Reinforced Plastics Derived from Plant Biomass

(A10)

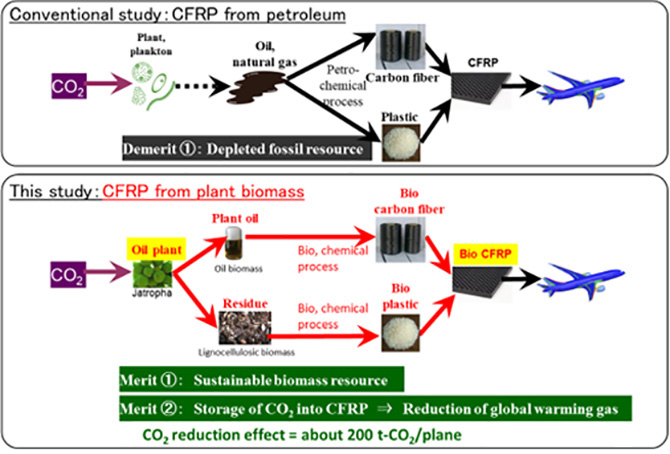

Concept and Approach

We are developing a technology replacing CFRP made from petroleum with plant biomass for a purpose of further increase of CO2 reduction effect in CFRP aircraft life cycle, and also as a countermeasure against the soaring oil price due to fossil resource depletion. It is said that the CO2 reduction effect would be 1.4 times to 5 times of the production weight at least when biomass products substitutes for petroleum-based plastics (trial calculation by Japan Organics Recycling Association). Therefore, when we use about 20 tons of carbon fiber and about 20 tons of base material resin for an aircraft (trial calculation by Japan Carbon Fiber Manufactures Association), CO2 reduction effect by replacing them from petroleum origin to bio-derived one would be ~ 200 tons / machine.

Unit Structure and Role

- Kobe University:

-

- Conversion from vegetable oil by enzymatic method to BDF and byproduct biomass (Consideration of basic conditions)

- Bio-energy Corporation:

- Conversion from vegetable oil by enzymatic method to BDF and byproduct biomass (Development of mass production technology)

- Kanazawa University:

- Production of materials for CFRP from byproduct biomass at BDF production (Consideration of basic conditions)

- Daicel Corporation:

- Production of materials for CFRP from byproduct biomass at BDF production (Development of production technology)

- IRII (Industrial Research Institute of Ishikawa):

- Conformity evaluation of conversion from plant biomass-derived material to thermoplastic CFRP

Research and Development

Oil plants are used as material plants for producing CFRP. Specifically, we manufacture carbon fiber monomer compounds and thermoset resin materials from byproduct compounds during producing biodiesel fuel (BDF) from vegetable oil.

As for lignocellulose, which is the main component of oil expression residue of vegetable oil, we produce thermoplastic resin by combining chemistry and biological reaction through pretreatment with normal temperature and normal pressure using ionic liquid. We manufacture CFRP from carbon fiber and thermoplastic resin obtained during the above process and evaluate its characteristic.

List of R&D Projects and Units

| No. | R&D Project | Research Unit | Unit Leader |

|---|---|---|---|

| A01 | Development of High Production Rate CFRP for Aircraft and Quality Assurance Technology | Thermoplastic Polymers and CFRTP | Masahiro Arai (Nagoya U.) Katsuyoshi Moriya (IHI) |

| A02 | Smart Manufacturing of OoA CFRP | Kenichi Yoshioka (TORAY) | |

| A03 | High Temperature CFRP and Validation | Yuichi Ishida (JAXA) Katsuyoshi Moriya (IHI) |

|

| A04 | Process Monitoring / Modeling for Quality Assurance | ◎☆Nobuo Takeda (UTokyo) ◎☆Yutaka Iwahori (JAXA) |

|

| A11 | High-rate Production / High Toughness CFRP | Toshio Abe (MHI) | |

| A10 | Development of Carbon Fiber Reinforced Plastics Derived from Plant Biomass | Kazuaki Ninomiya (Kanazawa U.) | |

◎:Co-Director of Research Domain ☆:Co-Manager