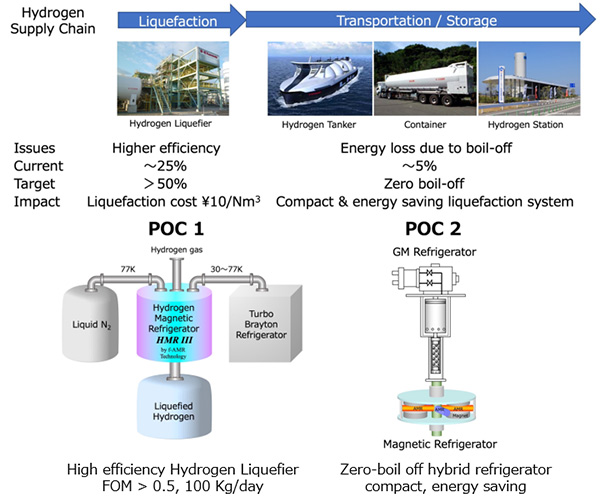

Technology theme: Innovative Hydrogen liquefaction technologies desired in future society

To realize a future society advanced in energy saving and carbon lowering, the utilization of liquid hydrogen is essential. Liquid hydrogen has as a volume 1/800 that of hydrogen gas, and advantages related to mass transportation, mass supply, mass storage, space saving, and super-high purity. The present hydrogen liquefaction process with a compressor has disadvantages, including low liquefaction efficiency at manufacturing and loss resulting from evaporation. The development of high-efficiency, low-cost, compact, durable, and innovative technologies for hydrogen liquefaction is expected to enable the mass utilization of hydrogen and contribute to an increased volume of hydrogen use for hydrogen power generation, storage of surplus power, and means of transportation.

Development of advanced hydrogen liquefaction system by using magnetic refrigeration technology

| R&D Period | 2018.11- |

|---|---|

| Grant Number | JPMJMI18A3 |

| Project Summary | Summary |

Summary:

For the supply chain of hydrogen, liquefaction cost may occupy 1/3 of total supply price, therefore, developing a high efficient hydrogen liquefier is one of the most important technology issues for incoming hydrogen society. Magnetic refrigeration using the magneto-caloric effect has potential to realize liquefaction efficiency higher than 50%, and also to be environmentally friendly and cost effective. A hybrid refrigeration cycle consisting of precooling cycle and magnetic active regenerator cycle has been proposed and estimated to achieve a liquefaction capacity of 100 kg/day with FOM = 0.5. Our new project is committed to develop

① such a high efficient hydrogen liquefier and also,

② compact and energy saving re-condensation refrigerator to realize zero boil-off in the liquid hydrogen storage.

R&D Team

[Leading Institution]

National Institute for Materials Science (NIMS)

[Collaborators]

National Institute for Materials Science, Kanazawa University, NIT Oshima College, Kyoto University, Kyushu University, National Institute of Advanced Industrial Science and Technology, Mayekawa MFG., Nippon Yttrium, CHUBU Electric Power, Sumitomo Heavy Industries, Iwatani

Project Website

|

Affiliation and job title should automatically appear from the information that a researcher registered with researchmap.

Data may be outdated or undocumented. When there is not a connection via the internet, data are not displayed. |