Materials Integration

Domain A

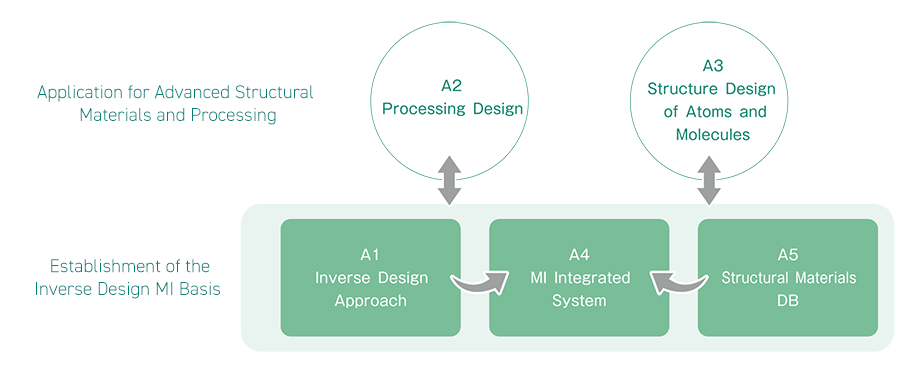

Establishment of the Inverse Design MI Basis for Advanced Structural Materials and Processing

AIM

The establishment of an integrated materials development system aiming to realize Society 5.0, which proposes required structure and properties of materials to fulfill desired performance and also enables presentation of its potential processing. We will also further develop advanced structural materials and processing, in which Japan has strength and the importance of which will increase in future.

Research teams and their roles in the domain A

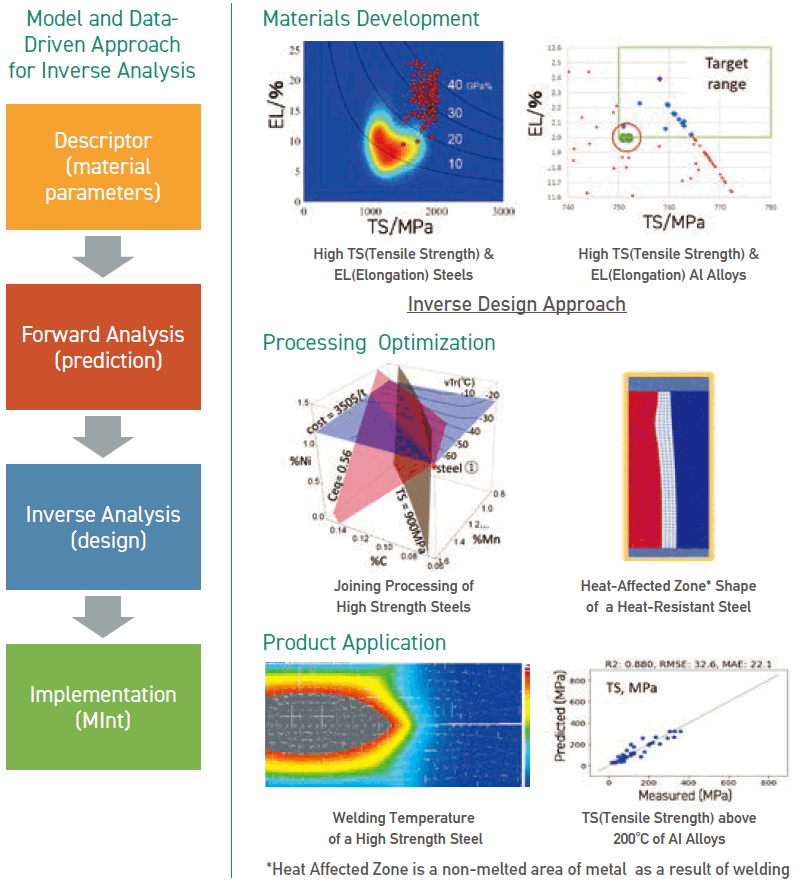

A1 Inverse Design ApproachEstablishment of the Inverse Design MI Basis

We aim to realize the inverse design approach on the following themes of "Materials Development(*1)","Processing Optimization(*2)", and "Product Application(*3)".

*1 : for next generation high strength steels and Al alloys

*2 : for joining processing of high strength steels and heatresistant steels

*3 : for welding strength of high strength steels and hightemperature strength of Al alloys

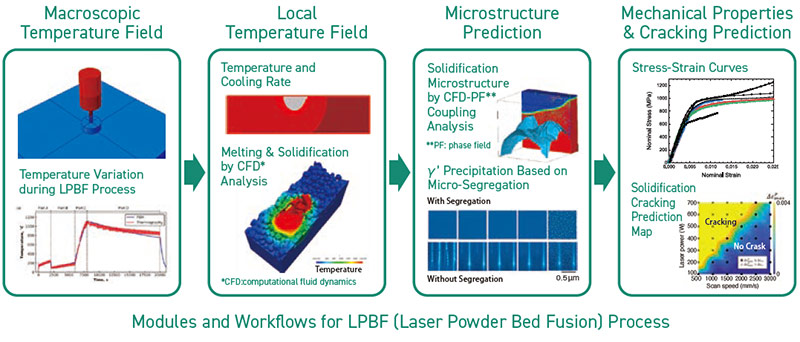

A2 Processing DesignApplication for Advanced Structural Materials and Processing

We will develop MI system technologies to accelerate the development of nickel super alloys and titanium alloys, which are of crucial importance for the aerospace and energy fields. We will develop the modules and workflows necessary for predicting the performances of target materials and processing. By utilizing the inverse problem analyses, we aim to establish a method to suggest appropriate materials and optimal processing conditions for the performances desired by users.

- Powder Additive Manufacturing for Heat Resistant Alloys

- Powder Manufacturing Processing for Heat Resistant Alloys

- Powder Metal Forging for Heat Resistant Alloys

- Powder Sintering Processing for High Strength Alloys

- Ingot Metal Forging for Heat Resistant Alloys

A3 Structure Design of Atoms and MoleculesApplication for Advanced Structural Materials and Processing

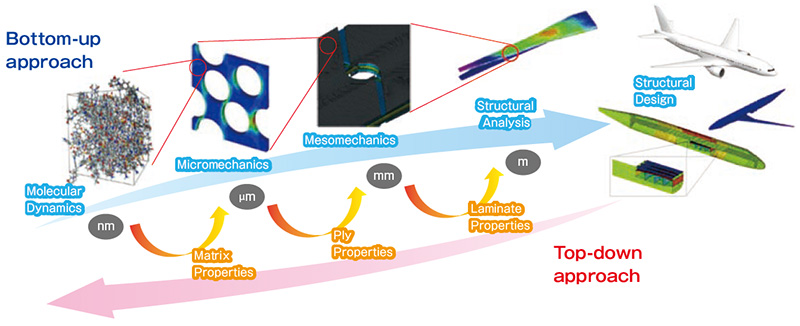

We will develop an integrated simulation tool which enables us to improve the thermomechanical properties of carbon fiber reinforced plastic(CFRP). This simulation tool includes the multi-physics/multiscale simulation code, which can handle the wide scale from atomistic to structure level. Moreover, the algorithm of inverse analysis will be implemented in the simulation tool.

To do this, following four themes will be addressed.

- (1)Atomistic Modeling

- (2)Mesoscopic Modeling

- (3)Multiscale Modeling

- (4)Inverse Design Approach

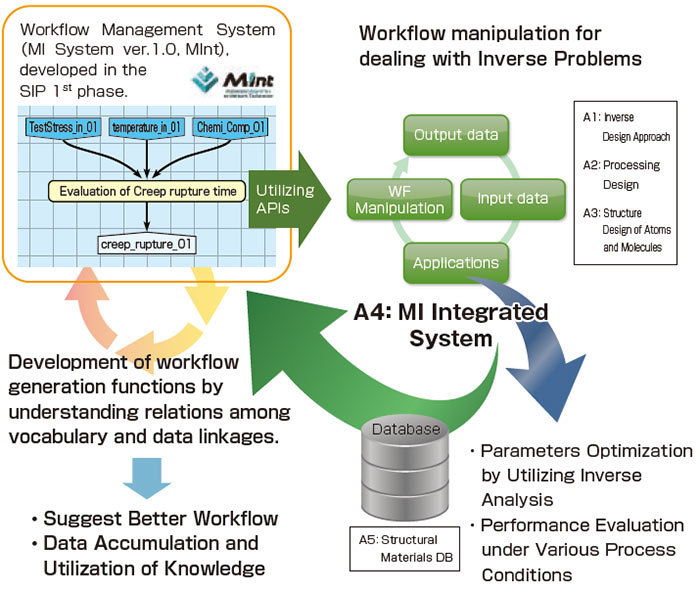

A4 MI Integrated SystemEstablishment of the Inverse Design MI Basis

By improving the MI System ver.1.0 (MInt), a system that will be able to treat difficult inverse design will be developed. Following, three themes will be taken account.

- Generalization of Inverse Design

- Development of Infrastructure for Inverse Design

- Verification for Actual Issues

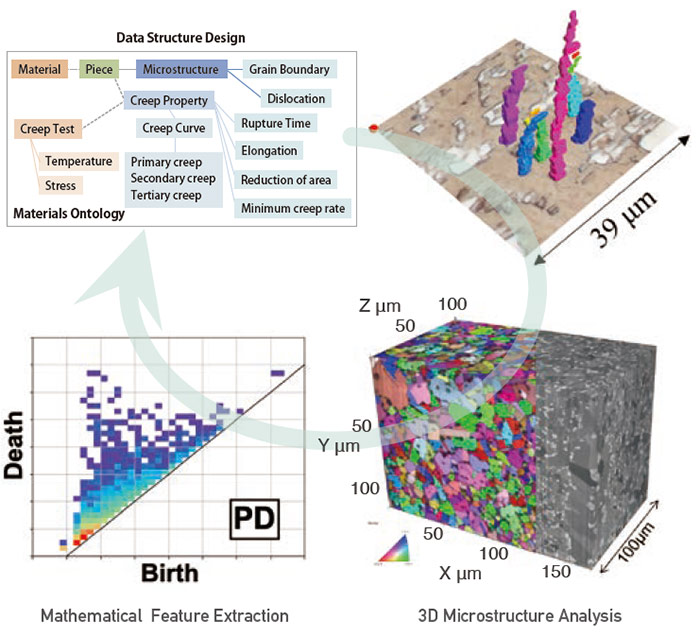

A5 Structural Materials DBEstablishment of the Inverse Design MI Basis

In order to establish data utilization methods in structural materials, we will address challenging themes regarding materials structure.

- Design of Data Structure for Structural Materials

- Development of 3D microstructure analysis

- Development of Mathematical Methods for feature extraction