Materials Integration

News

-

March 31, 2023

'Materials Integration for Revolutionary Design System of Structural Materials' has been completed in March 2023.

Program Director

-

Program Director

SIP "Materials Integration" for Revolutionary

Design System of Structural Materials

Yoshinao MISHIMA

President, Japan Agency for Medical Research and Development (AMED)

Professor Emeritus and former President, Tokyo Institute of Technology -

Deputy Program Director

SIP "Materials Integration" for Revolutionary

Design System of Structural Materials

Tetsuo MOHRI

Professor Emeritus, Hokkaido University

Greetings from the Program Director

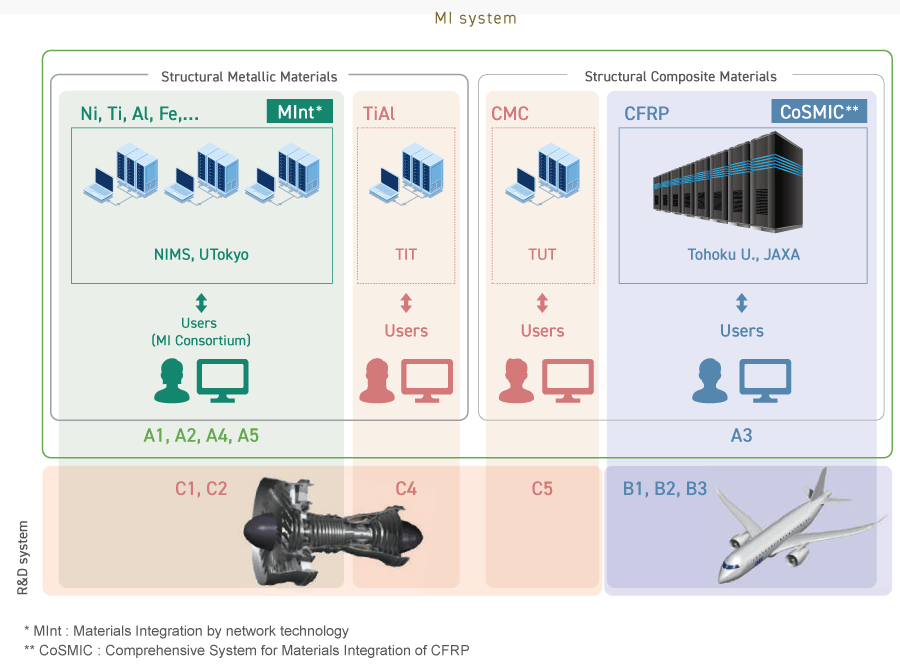

‘Materials Integration for Revolutionary Design System of Structural Materials’, one of the subjects of the Cross-ministerial Strategic Innovation Promotion Program (SIP)*, was started in FY2018 and is now in its final fiscal year. To strengthen the global competitiveness of Japan’s materials and related industries, world-first materials integration (MI) system are being developed which combine materials engineering methods, experiments, theoretical computations, and data science to connect processing, structure, property, and performance on computers to accelerate R&D. ‘MInt’ for structural metallic materials and ‘CoSMIC’ for carbon fiber reinforced plastics (CFRP) are our two main MI system, and systems for intermetallic compounds and ceramic matrix composites are also being developed. These systems contain inverse design functionality, which can form the conditions of materials and manufacturing processes necessary to realize a material’s desired performance.

Regarding practical results application, our goal is to have our MI system be broadly utilized by industry, academia and government to support their materials R&D. In the final fiscal year, we are installing computational modules and databases in the MI systems, verifying and validating them, and are also proactive in consortium activities. We strongly hope that the products and technologies developed using our MI system will be commercialized for real-world application. We appreciate your continued support for our endeavors.

July 2022

*SIP is a national program led by the Council for Science, Technology and Innovation( CSTI) of the Government of Japan, using interdisciplinary management to realize scientific and technological innovation.

Visit the Cabinet Office website

Research and Development

Materials Integration System

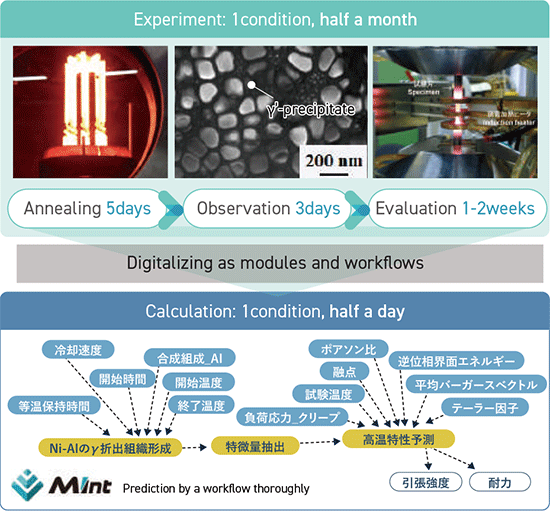

The major purpose of our MI system is to reduce costs and shorten development periods utilizing material engineering methods and data science that combine computational science, theory and experimentation, primarily by virtually reproducing materials events on a computer.

The MI system deals with cutting-edge structural materials and manufacturing processes. The main reasons for choosing structural materials are that their life time can be several decades long and accordingly their highly-precise R&D is timeconsuming and expensive. We aim to get benefits in shortening development periods and reducing costs from using the MI system.

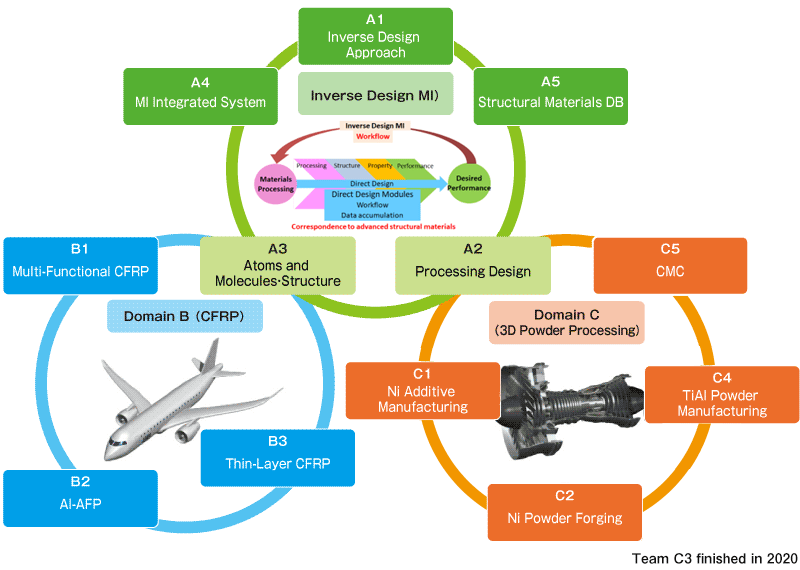

Our R&D system is composed of three domains with 12 teams (43 organizations in total). Domain A (A1 to A5) - establishment of the Inverse Design MI Basis; Domain B (B1 to B3) - applications to CFRP: Domain C (C1,C2,C4,C5) - application to 3D Powder Processing.

Domains B and C feed back physical data to Domain A and use the knowledge acquired by Domain A for actual materials and processing development, in order to verify and validate its effectiveness.

Overview of MInt (Materials Integration by network technology)

Based at the National Institute for Materials Science (NIMS), we are developing ‘MInt’ for structural metallic materials in cyberspace. By creating a workflow that connects computational tools called modules, we can predict processing, structure, property and performance in quick succession. As an example, an experiment that normally takes half a month can be shortened to half a day in cyberspace. Furthermore, we can combine MInt with other kinds of optimization methods in order to propose the optimal processing and structure considering the desired performance.

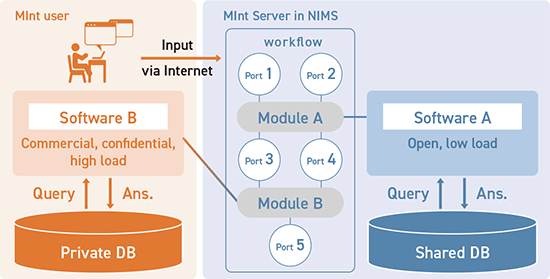

MInt has distributed computation functionality, through which a workflow can be computed in confidentiality. Each company can locally run a part of workflow in its own computing environment ensuring security when using its confidential data, and only the computed results are fed back outside to complete the computation of the workflow. We aim to make a user friendly system, available from distant locations via the Internet and supported with multimedia tutorials (MIntMedia).

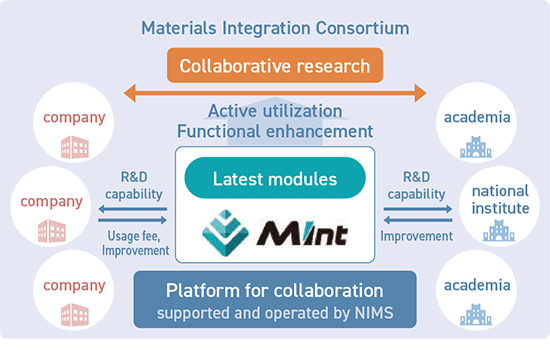

Overview of Materials Integration Consortium (MI Consortium)

In order to make MInt useful for society, NIMS manages the ‘Materials Integration Consortium (MI Consortium)’ established through industry-academia-government collaboration. The MI Consortium promotes material innovation through collaborative research based on MInt. And it is continually improving MInt by implementing modules and workflows developed through collaborative research, enhancing the R&D capacity of industry and academia members that use MInt.

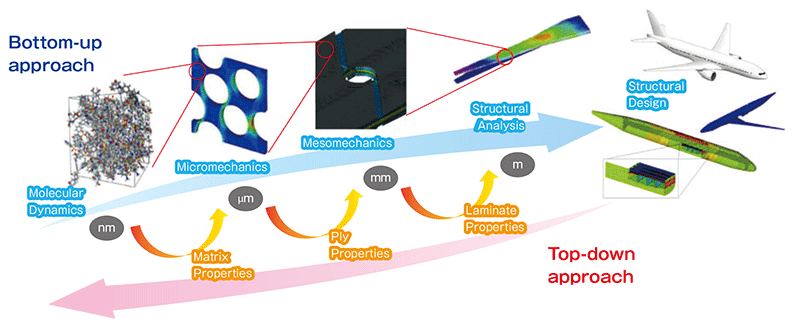

Overview of CoSMIC (Comprehensive System for Materials Integration of CFRP)

‘CoSMIC’ is being developed at Tohoku University as an MI system for carbon fiber reinforced plastics (CFRP). 12 modules aimed at CFRP design for aircraft structures have been developed so far, and multi-physics/multiscale simulations from atom to structure scale can be performed. In the future, in response to growing user needs, developing modules to support product development outside the aircraft industry is also planned.

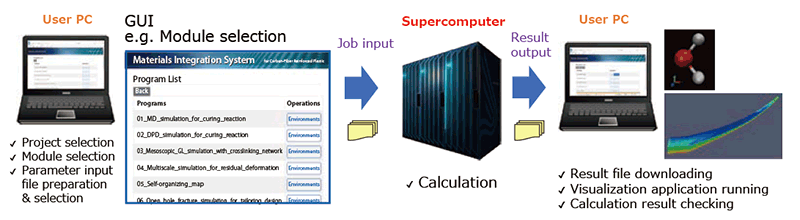

Users can access the system remotely and use the supercomputer at Tohoku University to perform large-scale and high-speed calculations. The system can be operated via a GUI and together with the easy-to-understand manual offers a userfriendly experience.

The consortium for CoSMIC

As with MInt, in order to promote the utilization of CoSMIC by many companies, the consortium was established in May 2022, and the system operation was started in earnest. 25 companies including non-participants of SIP attended the kick-off ceremony.

Research and Development Plan

“Materials Integration” for Revolutionary Design System of Structural Materials Summary(PDF:324KB)

Research and Development Items

-

Domain A

Establishment of the Inverse Design MI Basis for Advanced Structural Materials and ProcessingThe establishment of an integrated materials development system aiming to realize Society 5.0, which proposes required structure and properties of materials to fulfill desired performance and also enables presentation of its potential processing. We will also further develop advanced structural materials and processing, in which Japan has strength and the importance of which will increase in future.

-

Domain B

Applications of the Inverse Design MI to Actual Structural Materials(CFRP)The development of technologies related to the improvement of property and productivity of CFRP, which are becoming widely used as materials for lightweight structure, by integrated materials development system. This will enable us to lead the world in the development of transport equipment such as aircraft.

-

Domain C

Applications of the Inverse Design MI to Actual Structural Materials(3D Powder Processing)The realization of innovative materials and processes utilizing integrated materials development for 3D powder process of heat-resistant alloys with intense development competition and CMCs which are super high temperature heat-resistant materials for next-generation transportation and energy equipment, and this development will strengthen industrial competitiveness in Japan.

R&D Structure

Research and Development Overview(Domains / Teams)

Our R&D system consists of three domains with 12 teams – the Domain A (5 teams): the establishment of the Inverse Design MI Basis for Advanced Structural Materials and Processes (Inverse Design MI), the Domain B (3 teams) : the applications of the Inverse Design MI to Actual Structural Materials(CFRP)and the Domain C (4 teams): the application of the Inverse Design MI to Actual Structural Materials(3D Powder Processing). the Domain A carries out basic technology development of MI systems such as calculation modules, databases, workflows, inverse problem solution methods, and development into advanced materials and processing. The Domains B and C, as potential users, use the technology developed by the Domain A for the actual materials and processing development in order to demonstrate its effectiveness. The description of the R&D Overview is shown and the details will be described on the following pages.