Research Results

Towards solving the heat concentration problems in power semiconductors and high-performance CPUs

A high-efficiency cooling technology utilizing lotus metalsFY2022

- Lotus Thermal Solution Inc. /

Yuki Kazuhisa (Professor, Sanyo-Onoda City University) - Adaptable and Seamless Technology Transfer Program through Target-driven R&D (A-STEP)

- Company-led phase NexTEP-B type

- "high-performance in-vehicle cooler with spontaneous cooling promotion mechanism" (2017-2021)

Develops high-efficiency boiling coolers

The advanced electrification of today's automobiles has increased the amount of heat generated by their built-in devices, and sophisticated control of heating system is required. As a solution to this problem, we have developed a highly efficient boiling cooler (*1) utilizing lotus metals (*2). The heat generation density of SiC (silicon carbide), which is expected to be used as a power semiconductor in next-generation automobiles and electronic devices, is estimated to be 300 to 500 watts per square centimeter (W/cm2). Therefore, in order to use SiC as a device, it is necessary to cool it with a member that has a critical heat flux (CHF) (*3) higher than the above. In this development, we succeeded in improving the CHF from approximately 200 W/cm2 to 550 W/cm2 or more by using the boiling enhancement technology utilizing lotus metals. With the establishment of this technology, it is expected to be applied to the practical use of coolers for automobiles.

*1 Boiling cooling

A method of cooling a liquid refrigerant after it has been boiled by heat from a heat source. Unlike the conventional cooling method, which uses a temperature difference to transfer heat from a heat source to a refrigerant (water or air), the latent heat of evaporation (vaporization heat) during vaporization can be used, and the cooling capacity is reportedly several times greater.

*2 Lotus metal

a lotus-shaped porous metal with numerous slender pores arranged in the same direction. It has cooling characteristics by letting refrigerant flow through the pores.

*3 Critical heat flux (CHF)

When the heat load increases in boiling cooling, nucleate boiling with high heat transfer efficiency cannot be maintained at a certain point, and a sudden transition to film boiling occurs where the heated surface is covered with a vapor film. The heat flux (heat flow per unit area, unit [W/cm2]) at the transition point is called the critical heat flux.

The problem with loss of cooling capacities

For hybrid electric vehicles (HEVs), a highly efficient system using SiC power semiconductors in the motor control unit is being examined. However, as semiconductor packages become smaller in size, the power consumption per area of the semiconductor increases. In fact, since the heat generation density of SiC power semiconductors has increased from approximately 200 W/cm2 in Si (silicon) semiconductors to approximately 500 W/cm2, there is a need for a cooling system that can handle the higher heat generation density. Although the concentrated heat needs to be removed quickly so as not to exceed the limit of the heat resistance temperature of semiconductor devices, this is not easy to accomplish with the current circulating water cooling system. Meanwhile, the boiling-cooling method, which uses the latent heat of evaporation (heat of vaporization) of the refrigerant, has a higher cooling heat flux than the water-cooling method, and has long been employed in devices that require high cooling efficiency (Fig. 1). The boiling-cooling method, however, has the problem that if heat exceeding the critical heat flux (*3) flows into the surface that transfers heat to the refrigerant (heat transfer surface), the cooling capacity is rapidly lost. The aim of this development is to solve this difficulty of the boiling-cooling method and to put it into practical use as a cooling technology that can handle a higher heat flux and can be applied to a wide range of applications, including automotive applications.

Fig. 1 Cooling methods and their heat transfer performance

The heat transfer performance by water refrigerant in each cooling system is shown. The heat flux of the boiling-cooling method is 50 times or more higher than that of the circulating water cooling method. The cold heat flux derived from this new technology is twice or more the conventional water-refrigerant boiling method.

Boiling coolers with water refrigerant for automotive applications

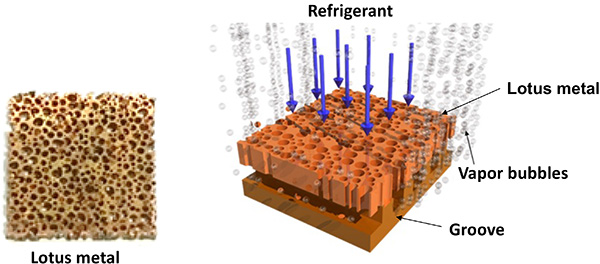

This development was based on the research results on the boiling heat transfer effect by Professor Kazuhisa Yuki at Sanyo-Onoda City University. Thermal conductors such as copper with grooves about 1 millimeter (mm) wide carved into them at regular intervals ("groove") were fabricated for contact cooling of heating elements. The combination of the "groove" and the lotus metal has resulted in a structure that is less prone to phenomena that inhibit the cooling of heating elements (Fig. 2). Furthermore, we found that the dimensions of grooves and pores of the lotus metal are important factors in determining its cooling performance, and established a method to determine the appropriate cross-sectional area of the grooves and pore diameter depending on the refrigerant. As a result, CHF of 550 W/cm2 or more and CHF of 270 W/cm2 were achieved for small (cooling surface of 10 mm x 10 mm) and large size (cooling surface of 65 mm x 65 mm) boiling coolers, respectively, as a boiling cooler using water refrigerant for automotive applications. When this developed technology was applied also to a prototype of boiling cooler using a fluorine-based inert liquid (*4) refrigerant, it was shown that the flow of the generated vapor and refrigerant were separated, enabling both rapid discharge of vapor and stable supply of refrigerant (Fig. 3). This result confirms that the technology developed is effective for the design of coolers that use different solvents.

We also examined the application of fluorine-based inert liquid refrigerant to CPU coolers for workstations (high-performance computers for business use), and showed that the prototype can achieve cooling performance equivalent to that of existing products with a half cooler volume.

*4 Fluorine-based inert liquid

A general term for organic solutions containing fluorine. Fluorine-containing organic solutions are electrically insulating, chemically inert, non-toxic, and have a variety of boiling points.

Fig. 2 Effect of boiling heat transfer

The combination of the lotus metal and the "groove" (a metal plate with a groove structure and good thermal conductivity) is used to boil the refrigerant to prevent film boiling.

(Left) The lotus metal with unidirectional pores like lotus root.

(Right) Cooling liquid is drawn in from the top of the lotus metal, and vapor is discharged from grooves on the "groove" surface.

Fig. 3 Relationship between cooling surface temperature and cooling performance

The cooling surface temperature and heat flux were obtained using a water refrigerant (red circle) and a fluorine-based inert liquid refrigerant (blue triangle) by experiments using a boiling accelerator.

(a) Purple part: performance area used for cooling the server

(b) Yellow part: performance area used for Si power semiconductor applications

(c) Light blue part: performance area expected to be used for SiC power semiconductor applications

Toward an early commercialization with results that exceed the research targets

The tendency that the concentrated heat generation increases with the miniaturization of semiconductors is considered to be a continuing problem, and the demand for coolers with high critical heat flux will grow. In this development, a prototype for use as a CPU cooler by manufacturers was achieved, and results exceeding the target were obtained, which may lead to early commercialization.

The resulting boiling cooler is capable of cooling inverters (*5) with Si and SiC semiconductors, and is expected to be a technology that solves the problem of heat concentration in automotive power semiconductors, which are generating higher heat densities. Furthermore, this could be a highly efficient cooling technology for workstation CPUs and large servers installed in data centers. The current research will contribute to the promotion of Target 7.3 of the Sustainable Development Goals (SDGs): "By 2030, double the global rate of improvement in energy efficiency".

*5 Inverter

A circuit or device that converts direct current into alternating current. It provides high-quality electricity.

- Environment and Energy

- Research Results

- Japanese