Research Results

Accelerating practical application of future generation storage batteries

Higher performance of magnesium metal batteries achievedFY2022

- Kanamura Kiyoshi (Professor, Graduate School of Urban Environmental Sciences, Tokyo Metropolitan University)

- Advanced low-carbon technology research and development program, ALCA

- Next-generation storage battery project

Team Leader of "Next Generation Battery Team" (2013-2022)

Succeeded in significant improvement of magnesium metal battery characteristics through a new material development approach

The move toward decarbonization, which aims to achieve "substantially zero" greenhouse gas emissions that cause global warming, is accelerating. Renewable energies using wind power and solar power, which are the trump cards for decarbonization, are easily affected by the weather, and it is difficult to stabilize the amount of power generated. Therefore, a system that can store and supply energy whenever necessary is indispensable, and the importance of storage batteries is increasing.

Currently, lithium-ion batteries that are widely used as storage batteries from mobile applications to EVs contain rare metals such as cobalt and lithium, requiring enormous costs to promote global decarbonization. In addition, there is a safety issue due to the instability of lithium in the atmosphere. Therefore, attention is focusing on magnesium metal batteries that use materials with abundant resources, and can store a large amount of electrical energy.

The research team has succeeded in significantly improving the cycle characteristics and capacity of magnesium metal batteries that are expected to be used as storage batteries offering low-price, larger capacity, and safety.

The key was to work on new technologies and materials related to positive and negative electrodes, which had been an issue for making high-performance magnesium metal batteries. For the positive electrode, new material design guidelines were established for oxide-based positive electrodes that realize high capacity, high cycle characteristics by introducing a new diffusion path and storage site for magnesium ions. For the negative electrode, the world's first method to improve battery characteristics was devised by making a metal alloy and controlling its structure. As a result, a magnesium alloy with trace elements for the negative electrode material that improves the capacity of magnesium metal batteries by about 20%, compared to a pure metal negative electrode, was developed.

Addressing the issues facing positive and negative electrodes of batteries

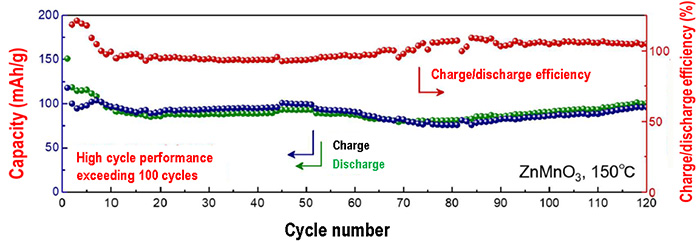

In the study of positive electrodes, the team searched for positive electrode materials suitable for magnesium metal batteries. New material design guidelines for oxide-based positive electrodes were established. Positive electrode materials that show high cycle characteristics reported for magnesium metal batteries are limited to sulfide-based materials that have 1 volt-level potential differences relative to magnesium, and the energy density (*1) cannot be expected to improve. There was a strong demand for the development of feasible oxide-based positive electrode materials that can achieve higher potentials. This research focused on spinel-type oxides that show high potential and high capacity (*2), but the problem is that they have poor cycle characteristics (*3). With conventional materials, a phase transition to a rock salt type structure (*4) easily occurs due to the insertion (discharge) of magnesium ions. It was thought that the rock salt phase, in which magnesium ions diffuse slowly, and which covers the surface of the active material particles, hindered charge and discharge, and that fracture of active material particles due to local strain at phase boundaries led to cycle deterioration. By using ZnMnO3, which is a Zn-Mn-based defect spinel-type oxide, to suppress cycle deterioration, it was possible to realize high cycle characteristics that dramatically surpass conventional materials while maintaining high potential (2 to 3-volt class) and high capacity (approx. 100 mAh/g).

Fig. 1 Magnesium metal battery positive electrode characteristics of new defect spinel-type oxide material ZnMnO3

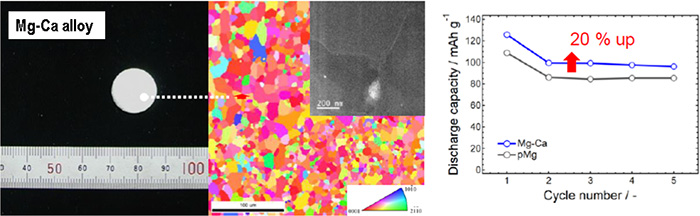

In the study of negative electrodes, the team worked on elucidating the composition and structure of negative electrodes that are optimal for magnesium metal batteries. Researchers specializing in electrolyte development and researchers specializing in the development of magnesium alloys as structural materials, conducted joint research to search for magnesium alloys that improve battery characteristics. As a result, by controlling the crystal orientation (*5) and adding a very small amount of a dissimilar metal at an atomic concentration of 0.3% to a magnesium (Mg) metal material composed of minute crystal grains of about 20 μm, the electrochemical activity was greatly improved. For example, when a prototype battery was manufactured using an alloy material (Mg-Ca) to which calcium (Ca) had been added as the negative electrode, evaluation of its characteristics revealed that there was approx. 20% improvement compared to a battery using pure magnesium metal (pMg), (Fig. 2). This is the world's first achievement to improve battery characteristics by alloying magnesium metal and controlling the structure.

Fig. 2 (Left) Photograph of the new Mg-Ca alloy material, (Center) Observed microstructure of the new material, (Right) Battery charge/discharge test results using pMg and Mg-Ca material as the negative electrode

*1 Energy density

It shows the amount of energy stored per unit weight (volume), and is an important evaluation index for storage batteries.

*2 Spinel-type oxide

An oxide having a crystal structure called a spinel-type structure, and since it has a three-dimensional network in which ions can diffuse in the crystal structure, it is also used as a positive electrode material for lithium-ion batteries.

*3 Cycle characteristics

Changes in battery performance (mainly battery capacity) due to repeated charging and discharging.

*4 Rock salt type structure

A dense crystal structure in which all octahedral sites are occupied by cations, while having the same oxygen ion arrangement as the spinel-type structure.

*5 Crystal orientation

Atoms, which are the smallest units that form a metal, are regularly arranged in a solid. Arrays have periodicity, and the smallest unit is called a unit lattice. Unit lattices are roughly classified into six types according to the arrangement of atoms, and magnesium metal consists of hexagonal lattices. The planes of the unit lattice are called crystal planes, and in a crystal that is an aggregate of unit lattices, the crystal planes are arranged at equal intervals. The direction of this arrangement of crystal planes is called crystal orientation.

Material development for magnesium metal batteries actively pursued

The results of this research pave the way for improving the performance of positive electrodes for magnesium metal batteries, which has been an issue for many years. Since the general design guidelines for oxide-based positive electrode materials suitable for magnesium metal batteries have been established, it is expected that the development of derived materials will become more active worldwide in the future. A material suitable for the negative electrode for magnesium metal batteries, which had been unknown until now, was also successfully developed. By gaining new knowledge about positive and negative electrodes, it is expected that accelerated research and development will allow the realization of magnesium metal batteries, which will become the next generation of batteries.

- Environment and Energy

- Research Results

- Japanese