Research Results

Culturing muscle cells in a three-dimensional structure using an innovative method

World's first dice steak-like cultured meatFY2021

- Takeuchi Shoji (Professor, Institute of Industrial Science, The University of Tokyo)

- JST-Mirai Program

- "Realization of a sustainable society", "Development of the production technology for next generation-meat using 3D tissue engineering techniques", Project Leader (Feasibility Study: FY 2018-2019, Full-scale: FY 2020-)

Production of thick meat chunks in vitro

Professor Takeuchi Shoji and his colleagues succeeded in producing the world's first dice steak-like "cultured meat". Although research on cultured meat is being actively undertaken all over the world it is difficult to prepare thick cell tissue, and most of the cultured meat so far has been minced. In contrast, this study aims to produce lumps of cultured meat and developed a technology to produce the three-dimensional structure of muscle tissue in vitro making full use of cutting-edge life science and engineering. In March 2019, they were able to produce large three-dimensional muscle tissue with dimensions of 1.0 cm x 0.8 cm x 0.7 cm, and took the first step toward creating dishes that cannot be made with minced meat and practical use of chunky cultured meat suited to various food cultures.

Fig. 1 Large muscle fibers like dice steak

Tackling the problems of population growth and global warming

It is estimated that the world population will reach 9.7 billion in 2050. Viewing that meat consumption is likely to increase when the economic situation becomes better, meat consumption would be expected to increase to 1.8 times that of 2010. However, it is difficult for conventional livestock farming methods to respond to population growth and demand growth on such a scale, and problems on aspects such as environment, safety, and ethics have been pointed out. For example, with current livestock farming methods, 25 kilograms of corn and 20,000 liters of water are required to produce 1 kilogram of beef, and the production efficiency is very low compared to vegetable foods. In addition to feed and water, vast tracts of land are required to increase meat production; and illegal deforestation to secure the space has become a serious problem. There is also concern that a large amount of methane gas emitted from livestock manure will promote global warming.

Further, there is always a risk of infectious diseases being transmitted from livestock animals to humans, and at present, antibiotics are administered to livestock animals during breeding to ensure safety.

In terms of ethics, despite the fact that meat is obtained by sacrificing animals, a considerable amount of meat is discarded due to reasons such as the expiration date.

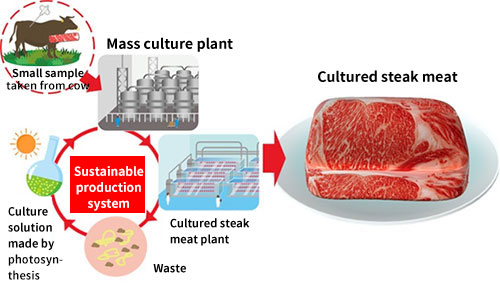

"Cultured meat" has been attracting attentions as one method to build a sustainable recycling-oriented society that leads to the solution of these problems.

However, the mainstream of cultured meat so far has been minced meat that collects cells. Although this is close to the stage of commercialization, the technology for making thick chunks of meat has not yet been developed. Therefore, in this study, they are developing technology for producing thick cultured meat that has the same texture as real meat; and at the same time, they are working on methods to reduce cost, so that it can actually be used as a new animal protein source.

Fig. 2 Sustainable society that this study aiming to achieve

https://www.jst.go.jp/pr/info/info1425/pdf/info1425.pdf

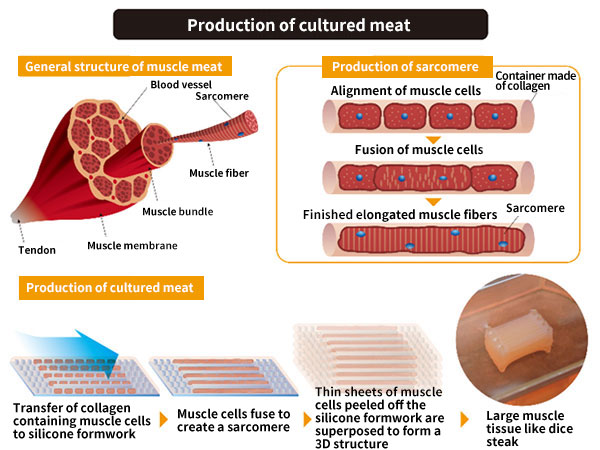

New method enables the 3D structure of muscle tissue

In addition to the cost, the taste and texture are also important for the acceptance of cultured meat by society. This study aims to reproduce the 3D structure of the muscle tissue of real meat to bring the cultured meat closer to the original texture.

To create a 3D structure in vitro, not only the number of muscle cells must be increased, but also the cells must be matured and fused with each other to create an elongated fibrous tissue (muscle fiber) that have a unique pattern, called a sarcomere. It was confirmed that giving vitamin C to muscle cells and distributing necessary nutrients promotes maturation even in vitro.

Cells are generally cultured in a container such as a petri dish; however, the method cultures only 2D-structured cells and grows muscle fibers in random directions. In this study, cells were 3-dimensionally cultured in a collagen gel placed in an elongated formwork to create a 3D structure in which muscle fibers were oriented in the same direction in a three-dimensional manner, like actual muscle tissue. With this method, muscle tissue with aligned fibers was successfully produced. Further, stacking these muscle fibers in a sheet shape and culturing them by a special method made it possible to produce the world's first large, three-dimensional muscle tissue. The results of this study are expected to be used in the field of drug discovery.

Fig. 3 Production of three-dimensional cultured meat

https://scienceportal.jst.go.jp/gateway/sciencewindow/20191024_w01/

Development of low-cost, safe and delicious cultured meat

By extending these studies, it would be possible to create even larger muscle tissue in the future. Looking ahead to the practical application of "cultured steak meat" that has the original texture of meat, the research project has been upscaled and expanded to an all-Japan team in FY2020 for further research and development. To make it easy for people to accept this as food, the research aims to reproduce not only the size but also blood vessels and fat, and make it as close as possible to real meat.

To reduce costs, development of the mass culture of cells has been attempted using algae that grow by photosynthesis as a nutrient source to establish meat production technology that achieves both deliciousness and low cost.

By putting cultured steak meat into practical use, it will be possible to contribute to responding to population growth and food production increase, and to curb environmental problems. Moreover, since it is produced in an extremely hygienic environment, it is expected that this will lead to securing an extremely safe meat supply without having to worry about infectious diseases derived from livestock animals.

- Life Science

- Research Results

- Japanese