Research Results

Sustainable Energy

Enhancing conversion efficiency of organic-inorganic hybridized perovskite solar cells FY2017

- Tsutomu Miyasaka (Professor, Graduate School of Engineering, Toin University of Yokohama)

- ALCA

- Enabling Technology Project: Next-generation smart communities with autonomous distributed system

Leader of research into organic-inorganic hybrid high efficiency solar cell development (2013-2016)

Perovskite solar cells are garnering attention around the world

Solar cells directly convert sunlight energy into electricity. There are a variety of different types of solar cell and these c an be grouped based on the various semiconductors they use. Most mass-produced solar cells are silicon- or compound-semiconductor-based cells. While these kinds of solar cells are robust an d of high power conversion efficiency (the better ones achieve efficiency of 25%), materials and production costs are relatively high. In addition, the silicon in silicon-based solar cells nee ds to be thick, meaning that the cells cannot be bent and this limits where they can be installed.

A crystalline material called perovskite is now keenly anticipat- ed as a promising material for use in next-generation solar cells. Perovskite solar cells can attain a conversion efficiency high enough to rival those of silicon and compound-semiconductor solar cells. Perovskite films are thin (<0.5 μm) and easy to be prepared by solution processes such as spin-coating and slot die coating technologies, making perovskite solar cells less expen- sive than existing types. Technologies of perovskite also make it possible to create lightweight and flexible solar cells that can be installed in places where rigid silicon solar cells are difficult to be applied. There have been no alternative types of solar cells with these merits and high conversion efficiency that can compete with silicon solar cells.

Perovskite solar cells are currently enjoying the central atten- tion in the solar cell field, and the majority of papers on photo- voltaics and solar cells around the world now relate to perovskite solar cells.

It was Professor Tsutomu Miyasaka who in 2006-2009 first pro- posed the use of these revolutionary solar cells. He has partici- pated in the "Solar Cell and Solar Energy Systems" initiative of "Advanced Low Carbon Technology Research and Development Program" (ALCA) , JST since 2013, and is now carrying out world-class R&D of organic-inorganic hybrid high efficiency solar cells as part of an ALCA Enabling Technology Project.

The structure of Organic lead halide perovskite

The chemical formula of the perovskite crystals, which absorbs entire visible light up to 800 nm, is NH3CH3PbI3. Prof. Miyasaka was the first person in the world to use this material as sunlight absorber for solar cells.

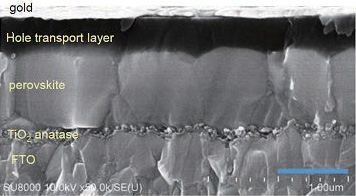

Producing perovskite solar cells requires perovskite film formation by solution coating processes. First of all, a solution containing the source materials is applied to a metal oxide meso- porous surface (titania, zinc oxide, alumina, etc.) to create a thin film of perovskite crystals, which is capable of visible light absorption up to a wavelength of 800nm. On the top of per- ovskite film is coated an organic hole transport material which plays a role to electrically collect positive holes. Because cell fabrication processes are quick and easy, R&Ds of perovskite pho- tovoltaic cells are now being conducted at a large number of different institutions and rapid advances are being made with the enhancement of conversion efficiency and cell stability.

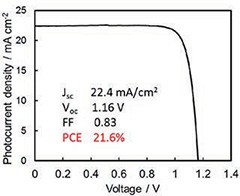

Through their research activities at ALCA aimed at optimizing materials, crystalline structures, and processes, Prof. Miyasaka and his team have achieved one of the highest conversion efficiency rates (21.6%) and a voltage output of 1.16V or more.

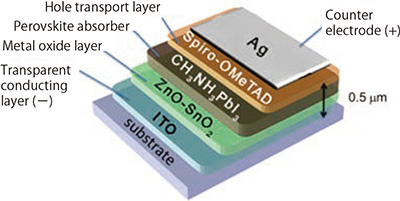

The highest efficiency of 21.6% was achieved based on low temperature process of cell fabrication which Prof. Miyasaka has been tackling for years in his research of photovoltaic cells. Low temperature process means preparation of metal oxide electron-collecting layers without needs of sintering treatment. This process makes it possible to use plastic films as electrode sub- strates on low cost roll-to-roll process, leading to manufacture of flexible, lightweight solar cells. Prof. Miyasaka demonstrated that plastic flexible perovskite cell works with efficiency more than 14% with sufficient mechanical stability against repeated bending.

The low temperature coating process

An example of the layered structure of perovskite solar cells made by low- temperature processes

Working toward the commercialization of flexible film-type solar cells

Perovskite solar cells have another major feature in production of thin flexible modules: Their modules can be produced at lower temperatures that do not damage plastic electrode substrates, making the production of thin plastic film-type solar cells.

Reducing the thickness of silicon solar cells makes them less able to absorb sunlight energy, causing a significant reduction in their conversion efficiency.

Perovskite solar cells, however, have a large sunlight absorp- tion coefficient, making it possible to produce thin film-type solar cells while maintaining good light harvesting power and high conversion efficiency.

If the conversion efficiency can be increased further and film substrate that is durable enough to withstand practical use can be produced, perovskite solar cells can be supplied as semi-trans- parent film-type solar cells. This contributes to supply high per- formance power devices for use in the consumer electronics and industry, typically applications to windows, indoor IoT devices, and portable electronic devices.

High efficiency perovskite solar cells made on plastic film. They retain stable performance levels even after being put through experiments in which they are bent 100 times or more.

Characteristics of a perovskite solar cell capable of 21.6% efficiency

Aiming to create perovskite-based tandem solar cells with a conversion efficiency of 30% or more

Efforts are currently being made to create solar cells with a tandem structure combining perovskite solar cells and other kinds of solar cells to attain a conversion efficiency of 30% or more̶much higher than that of conventional silicon solar cells (25% or less). Efforts are also being made to create highly reliable solar cells that can be used for 30 years or more. Moves are also being made to produce perovskite solar cells that con- tain no lead, a substance that has harmful effects on our health.

Through these efforts, it will become possible to create ideal solar cells that can be installed anywhere and that take up only small amounts of space while generating large amounts of energy, and thereby contribute to the reduction of CO2 emissions.