Realizing Ultra-Thin and Flexible Tough Polymers

Program Manager

Kohzo Ito

Kohzo Ito

1986 Doctor of Engineering, The University of Tokyo

1986-1991 Researcher & Senior Researcher, Research Institute for Polymers and Textiles

2003- Professor, The University of Tokyo

2005-2014 Director, Advanced Softmaterials, Inc

2014- ImPACT Program Manager

(cross appointment between the Univ. of Tokyo and JST; Effort: 80%)

1986-1991 Researcher & Senior Researcher, Research Institute for Polymers and Textiles

2003- Professor, The University of Tokyo

2005-2014 Director, Advanced Softmaterials, Inc

2014- ImPACT Program Manager

(cross appointment between the Univ. of Tokyo and JST; Effort: 80%)

Profile

He invented slide-ring polymer (SRM) with freely movable cross-links in 1999. He founded Advanced Softmaterials (ASM) Inc. in 2005 for the application of the remarkable toughness of SRM, and has been engaged in the management, research and development in ASM as well as the academic research.

He invented slide-ring polymer (SRM) with freely movable cross-links in 1999. He founded Advanced Softmaterials (ASM) Inc. in 2005 for the application of the remarkable toughness of SRM, and has been engaged in the management, research and development in ASM as well as the academic research.

What's New

Overview

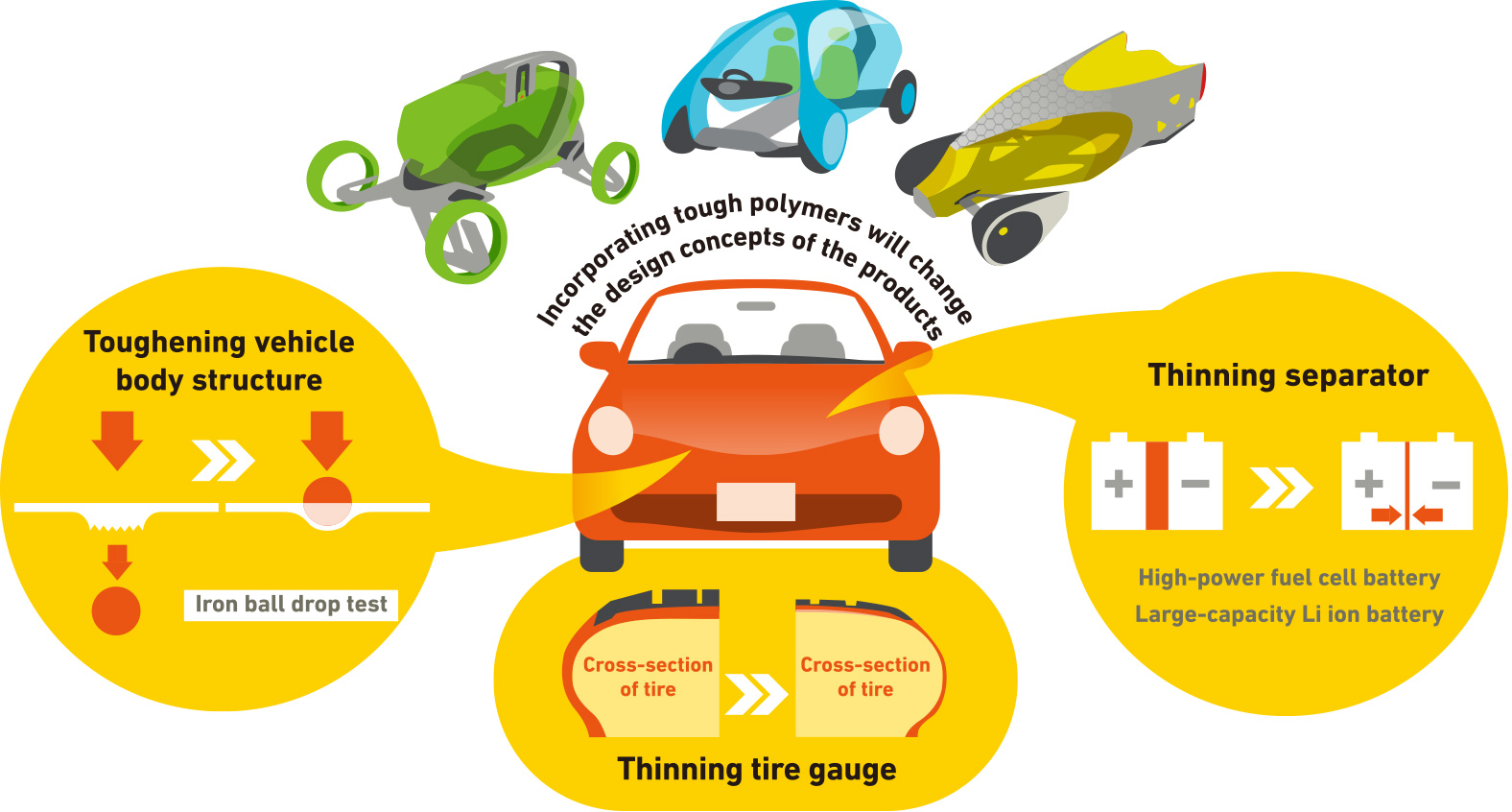

Polymers are so convenient that they are sometimes said to be the most versatile material ever developed by human beings. But the thinner they are, the more easily they tend to break, while if they are too hard, they become brittle. The goal of this program is to develop tough, flexible polymers that achieve both thinness and toughness exceeding conventional limits. Polymers that combine toughness, flexibility and self-restoring capability (the material recovers the damage in response to heat or light) will produce dramatic breakthroughs in automobile components and transport equipment. They will also have a widespread ripple effect throughout all industries that use polymeric materials, and in the future will meet society’s needs for safety, security and low environmental impact.

Disruptive Innovation

- Integrating cutting-edge facilities and advanced chemistry, we introduce novel molecular concept into conventional polymers with low cost. We break through the limit of industrialization for innovative high performance of ultra thin and flexible tough polymers.

- At a dramatic development pace, we strategically and efficiently achieve high toughness together with other functions that is impossible with the time-consuming trial-and-error approach using conventional technology.

The Challenges for the PM and the Impact of Success

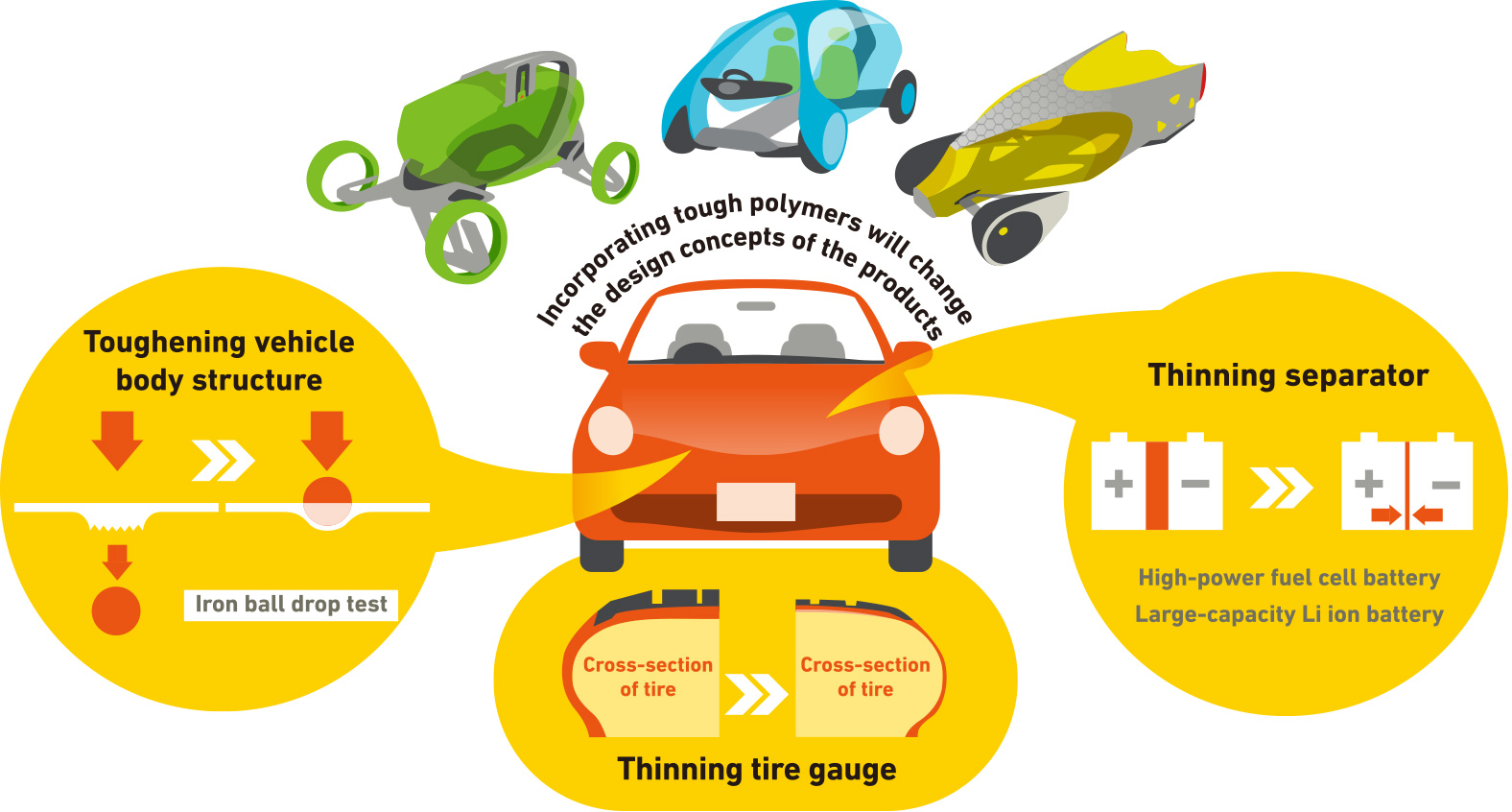

- Application of polymeric materials is rapidly growing in various industries beginning with the automobile industry. Thinning and toughening of polymers are very critical to balance high battery performance and light vehicle body with safety. Break through the limits of conventional thinning and toughening by clarifying the molecular mechanism of polymer fracture with SPring-8 and the K Computer and advanced polymer technology based on new molecular bonding and process engineering.

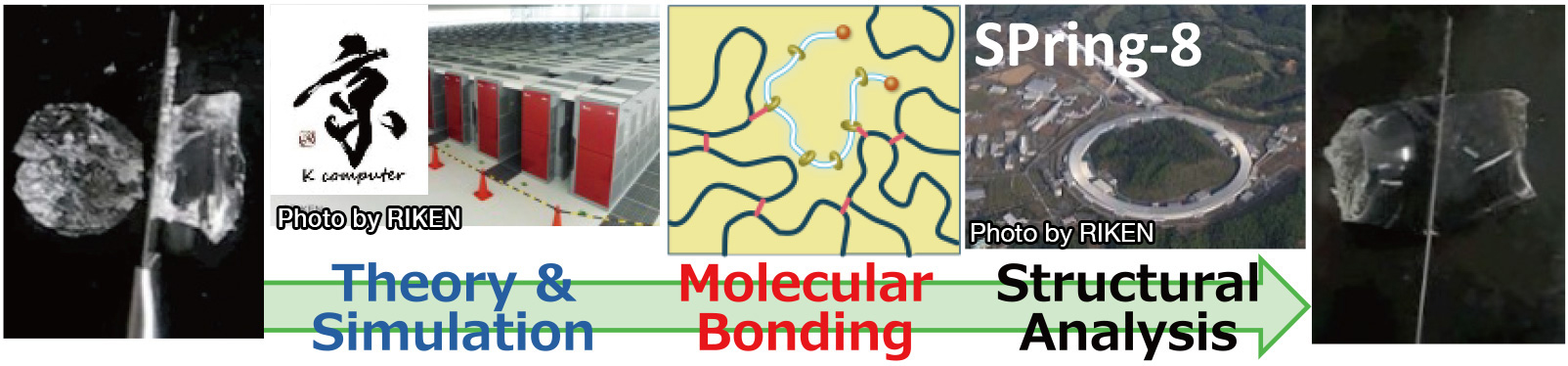

- Toughening polymers dramatically improves the performance of fuel cells, Li batteries, vehicle body, and tires, leading to the drastic weight reduction, reliability, and safety of vehicles.

- We dramatically revolutionize the industrial sector including automobiles by penetrating industry with the Tough Polymer master brand and realize a safe, secure, and low-environmental-impact society.

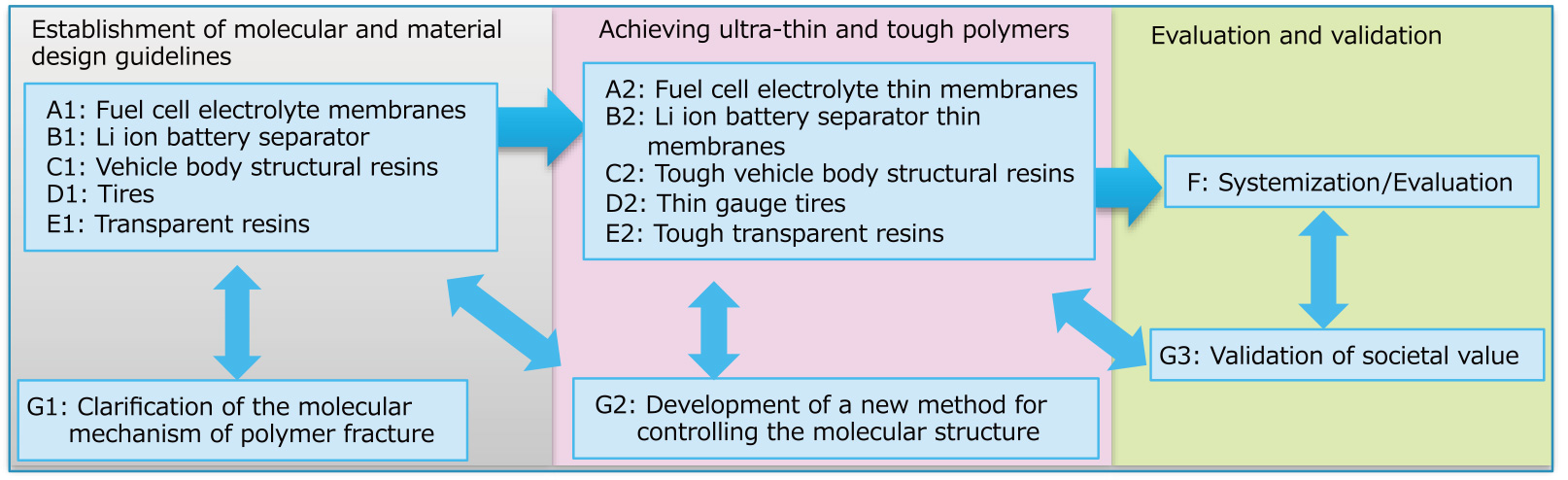

Scenario for Success and Achievement Targets

Scenario for success

- Bring together the world-class top-level experimental and theoretical knowledge. Link the theory for the macro-level fracture with the molecular mechanism to attain the essential origin of toughness by direct observation of the time-space hierarchy of polymer fracture in situ using SPring-8 and by huge scale molecular simulations on K Computer.

- Transfer the above results as feasibly executable knowledge to domestic companies that own world-leading proprietary technology and have a high capability to apply new technology to products and establish molecular and material design guidelines for achieving specific tough polymers.

- Strategically and efficiently realize innovative tough polymers by connecting the guidelines to new kinds of molecular bonding and polymer structures.

Furthermore, validate the industrial applicability of the developed tough polymers from the standpoint of an automobile manufacturer. - Aggressively implement competition and cooperation between development projects and cross-sectionally engage in common topics including the fracture mechanisms.

Achievement targets

- Realize ultra-thin fuel cell electrolyte/Li battery separator membranes, tough vehicle body structural/transparent resins, and thin gauge tires.

- Fabricate battery and vehicle body structure prototypes. Validate the polymer's industrial applicability as a system with demonstration experiments at a vehicle manufacturer.

- Establish molecular and material design guidelines for achieving tough polymers based on the molecular mechanism of polymer fracture.

- Develop a simple yet swift standard strength evaluation test method and prediction methods for fracture and fatigue life in a variety of environments, and establish long-term reliability of polymeric materials.

Overall R&D Program Structure Created by the PM

- What is the most difficult challenge is establishing the molecular and material design guidelines to achieve toughness while keeping the required performance. Avoiding the risk that comes with an inflexible program structure is critical for resolving the challenge. A structure will be developed in which academia can constantly provide adequate and precise support for the needs of companies and in which the PM will have the discretion to flexibly make changes to the overall structure for replacing, adding, and narrowing down the number of projects and participating institutions.

- Materials that have passed validations for systemization and evaluation for industrial applicability can immediately be transferred to the next stage of cost down and mass production for commercialization in view.

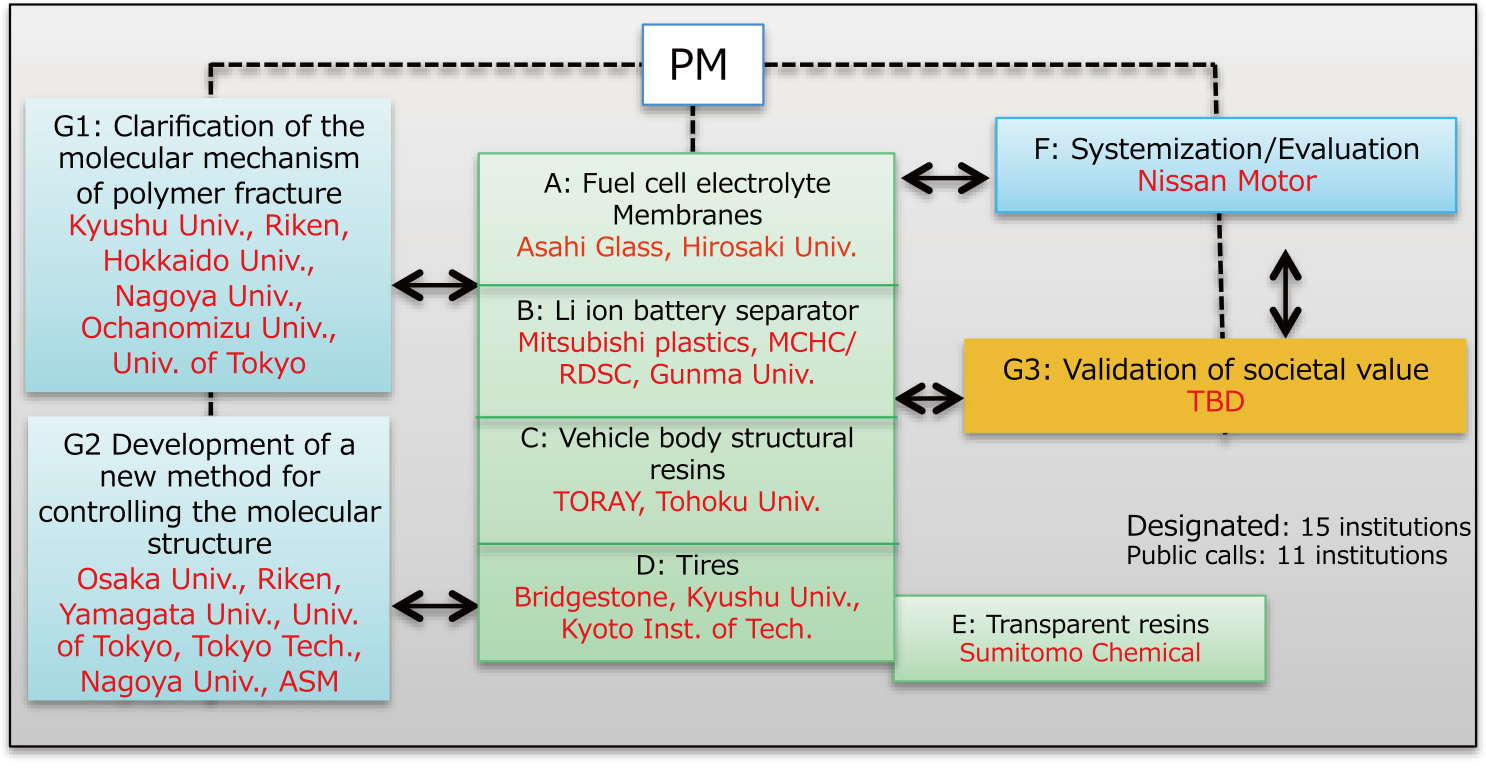

Implementation Structure as Assembled by the PM

- Industrial companies will lead the project from A to F, where the project leader (PL) will select the needed research institutions from among academia in G project. The G project covers common and cross-sectional challenges. This will create a strong industry-government-academia team that is optimized for resolving the challenges for each project.

- We selected industrial companies that own proprietary technology superior to competitors in areas outside of toughness and that are capable of influencing industry and society by achieving thin and tough polymers.

- We chose research institutes that have a track record and superior technology in experimental or theoretical research for tough polymers, and that have been selected by multiple PLs. Other institutions are added through calls for participants to complement the group and to implement competition and cooperation.

- The PM himself is affiliated with the Univ. of Tokyo. Since the PM invented the slide-ring polymer (one type of tough polymer) and the technology for its synthesis and property control is one of the common and key technologies for this program, participation of the Univ. of Tokyo is essential in achieving the target with adequate conflict-of-interest management.

Organization

The Cabinet Office

ImPACT: Impulsing Paradigm Change through Disruptive Technologies Program

ImPACT Program Manager

Kohzo Ito

ImPACT: Impulsing Paradigm Change through Disruptive Technologies Program

ImPACT Program Manager

Kohzo Ito

Associate Program Manager

Naoki Kato

Naoki Kato

Associate Program Manager

Tadashi Ishihara

Tadashi Ishihara