Research Results

Development of medical devices with highly workable super-elastic alloys

Correction of hallux valgus with copper-based super-elastic alloysFY2019

- Kouji Ishikawa(Executive Director, Special Metals Division, Furukawa Techno Material Co., Ltd.)

- Ryosuke Kainuma(Professor, Department of Materials Science, Graduate School of Engineering, Tohoku University)

- Masahito Hatori(Vice-President, MD, Tohoku Kosai Hospital)

- A-STEP

- Adaptable and Seamless Technology Transfer Program through Target-Driven R&D, Seeds Development Type

“Application of New Cu-Based Superelastic Alloy to Large-Scale Architectural Members and Hallux Valgus Correction Device” Project Leader/Research Director/Researcher (2011-2015)

Development of comfortable and easy-to-wear progressive orthosis

Furukawa Techno Material (FTM) is conducting a joint study with Tohoku University on "copper-aluminum-manganese shape memory alloys (copper-based super-elastic alloys) with copper as the main component and high elasticity. They successfully developed new copper-based super-elastic alloys with high workability and elasticity*. They further created a practical device to correct ingrown toenail, consisting of a copper-based super-elastic alloy plate, and are currently developing a hallux valgus correction device, which is a larger medical device, in collaboration with Tohoku Kosai Hospital.

Since super-elastic deformation stress does not strongly depend on the amount of strain, a constant corrective force can be applied regardless of the amount of deformation in nails and toes, and is well-suited to correction without discomfort. As it is flexible and effective in correcting severe deformation, easy to put on and off, comfortable, and can be customized for patients’ lifestyles, its convenience is considered ground-breaking.

The ingrown toenail correction device has been commercially available in medical facilities since 2011, on the Internet since 2014, and in drug stores since 2018. The hallux valgus correction device has been tested in trials in collaboration with doctors and medical device organizations. It has been improved after each trial, and its optimum thickness, shape, and structure are currently being identified. Since the copper-based super-elastic alloy is highly workable, super-elastic alloys could be used for a device with thickness of 0.4 mm and width of 15 mm, and a hallux valgus correction device was developed by examining the overall structure of the orthosis and materials for the parts that come in contact with the skin. This hallux valgus correction device can be worn for a long period of time without causing discomfort.

Since this device can be worn for a long period of time, its therapeutic effect has increased, and there have been new findings for conservative therapy. We have reported on these findings at many medical conferences so far. There are few cases in which a corrective device, other than surgery, was effective in treating hallux valgus; as such, the therapeutic effect of the present product is promising, and its early commercialization is anticipated. In the future, we attempt its market introduction via medical organizations.

The hallux valgus correction device made of a super-elastic alloy plate. It can be worn for a long period of time.

*It is flexible like rubber, and regains its shape quickly even after being greatly deformed.

Much awaited new shape memory alloys

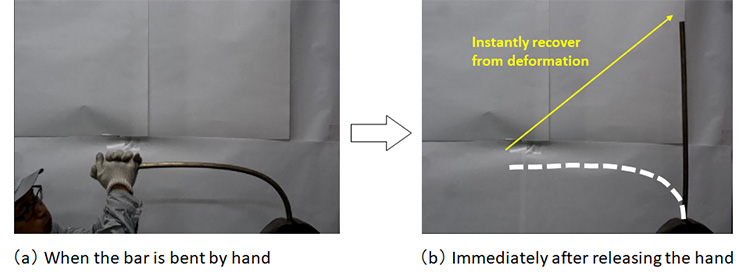

Shape memory alloys have a shape memory effect, in which the deformed material returns to its original shape when heated, and super elasticity. With 0.5% strain, usual metallic materials would remain deformed, but super-elastic alloys return to their own shape even with up to 8% strain as soon as the force is removed. It is being utilized for frames for glasses, orthodontic wires, stents, guide wires, and so on, for its shape memory properties.

Since nickel-titanic alloy was discovered in 1963, practical use of super-elastic alloys has dramatically improved; however, various super-elastic alloys that are being newly developed still have issues with workability and shape memory properties, and are not being put to commercial use as of yet. The majority of super-elastic alloys commercially available today are nickel-titanium alloys. However, nickel-titanium alloys are difficult to work with in terms of cold working*, and the cost of working with plates is high. Therefore, there is very little practical use, limited to simple lines and tubes. Thus, to expand the use of super-elastic alloys, mass production technology for copper-based super-elastic alloys with superior workability has been much awaited.

*Processing performed at room temperature or below the recrystallization temperature of the material. Since the metal is not exposed to excessive temperature, highly accurate processing is possible.

(Left) Normal metal. (Right) Super-elasticity of shape memory alloys.

Our research group has been working on research and development of copper-based super-elastic alloys since 1994. As a result, we discovered that by lowering the concentration of aluminum in the copper-based super-elastic alloys, its cold workability drastically improved, and about 60% cold workability could be achieved—twice that of nickel-titanium alloys in practical use—while maintaining its shape memory effect. Furthermore, by increasing the ratio of crystalline diameter (d) to the wire diameter (D) (d/D), we successfully achieved super-elasticity, in which the original shape can be almost completely regained even after 8% strain is applied. Based on these results, we actualized copper-based super-elastic alloys with high workability and elasticity, leading to the development of ingrown toenail and hallux valgus correction devices.

Discovery that broke through the common thinking in the field of metals

With its superior workability and properties, copper-based super-elastic alloys allow for manufacturing of shape memory alloy products, which were difficult to actualize in the past. At the same time, it has a unique mechanism in which, when copper-based super-elastic alloys are cooled and heated repeatedly in the temperature range of 900℃ or below, crystals of the metal grow drastically (abnormal grain growth phenomenon) (published in Science, 20131)).

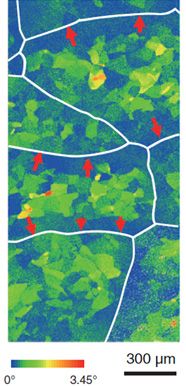

GROD map1) obtained by EBSD immediately after abnormal grain growth (white lines indicate the ground boundaries).

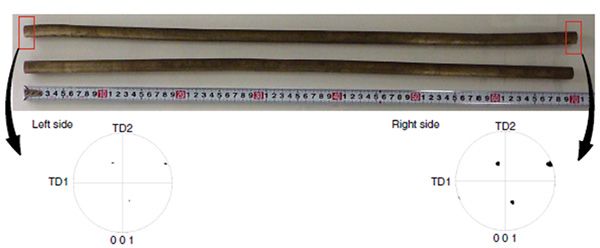

Based on the knowledge of abnormal grain growth phenomenon, we developed a manufacturing process consisting of only simple thermal process, which allows for mass production of copper-based super-elastic alloys. We have successfully manufactured a single crystal bar with a diameter of 1.5 cm and length of 70 cm, and confirmed that this bar material has a super elastic property (published in Nature Communications, 20172)). If this bar is used as a vibration control member, continuous strong shaking would not cause permanent deformation or damage, and we may be able to create earthquake-proof buildings in which the earthquake resistance does not deteriorate.

We have submitted eight patent applications regarding this technology, and have been granted rights both domestically and internationally. We plan to conduct concrete trials aimed at practical application within several years, and hope to contribute toward a safe and secure society.

Copper-based super-elastic alloy bars2), in which single crystal was grown to a massive size through thermal treatment.

References

1) Omori, T., Kusama, T., Kawata, S., Ohnuma, I., Sutou, Y., Araki, Y., Ishida, K. & Kainuma, R.: Science, 341 (2013) 1500-1502

2) Kusama, T., Omori, T., Saito, T., Kise, S., Tanaka, T., Araki, Y. & Kainuma, R.: Nature Communications 8 (2017) #354