Research Results

Environmentally friendly internal combustion engine

Achieving thermal efficiency of over 50% in passenger car enginesFY2019

- Norimasa Iida(Professor Emeritus, Keio University)

- Takuji Ishiyama (Professor, Graduate School of Energy Science, Kyoto University)

- Shigehiko Kaneko (Professor, Faculty of Science and Engineering, Waseda University)

- Daisho Yasuhiro(Senior Research Professor, Research Organization for Next Generation Vehicles, Waseda University)

- SIP

- Innovative Combustion Technology

Background and history

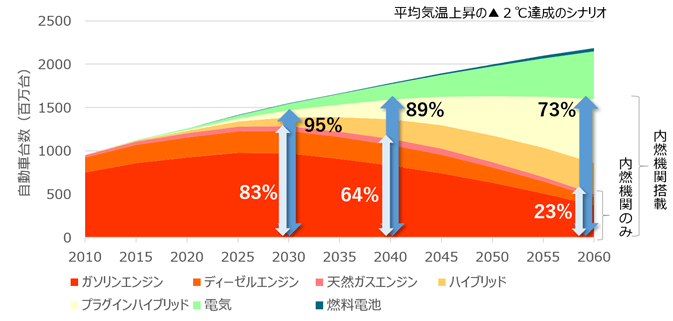

As vehicle electrification progresses, about 89% of vehicles around the world in 2040 would be equipped with an internal combustion engine. Therefore, to reduce the global CO2 emission, it is essential to improve thermal efficiency of internal combustion engines.

To dramatically improve thermal efficiency, it is necessary to create a new combustion concept to minimize energy loss wasted without being converted to power in the combustion process, and better regulate this combustion process.

To that end, we must scientifically elucidate combustion phenomenon that rapidly progresses in the engine via heat transfer, behavior of fluid, material transfer, chemical reaction, and their interactions, and develop technology based on such fundamental knowledge. In addition, in order to reduce energy loss, it is necessary to develop a technology that reduces structurally-unavoidable energy loss caused by the friction inside the rapidly moving engine, and a technology such as turbocharging and thermal power generation that utilize energy released as exhaust.

It is obvious that improving thermal efficiency can only be improved by integrating these findings and is a complex of cutting-edge science and technology.

Predicted composition of global vehicle ownership. Even in 2040, internal combustion engine is dominant.

(出典: ‘International Energy Agency (2018) , Global EV Outlook 2018、また以下データを用いてJSTで作成, 'International Energy Agency (2017), Energy Technology Perspectives 2017, OECD/IEA, Paris')

Content of the research

Due to such circumstances, at Cross-ministerial Strategic Innovation Promotion Program (SIP) "Innovative Combustion Technology", researchers from universities and public research organizations (hereafter universities) from wide range of fields—mechanical engineering, engine engineering, combustion science, heat transfer science, reaction chemistry, fluid dynamics, tribology, polymer chemistry, computational science, and so on—gather to work on research and development for the improvement of thermal efficiency.

In addition, based on a partnership agreement with JST, The Research association of Automotive Internal Combustion Engines (AICE) has conducted activities to universities, such as presenting needs of industry, providing experimental devices, and supporting safety assurance and device verification.

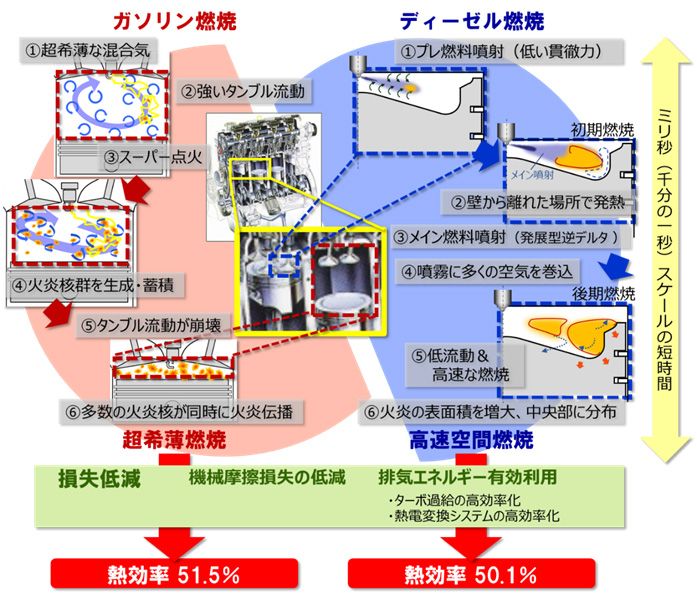

With such an industry-academia collaboration system, the following research results were obtained, and these results were integrated by matching conditions—such as temperature and flow rate of exhaust, and pressure generated by combustion—while giving consideration to synergetic and contradictory effects. In this manner, maximum brake thermal efficiency of 51.5% and 50.1%, respectively, for gasoline engine (spark ignition engines) and diesel engine has been achieved successfully.

1. Research and development on improved efficiency of gasoline combustion

- Combustion concept: "Super-lean burn"

- Challenges in actualizing the concept: It is difficult to ignite with the conventional ignition technology. Even if it is partially ignited with large discharge energy, there is a large variation between when the flame propagates and when it does not, and combustion is unstable.

Implementation content and results: Powerful tumble flow (longitudinal vortex) was introduced to a super-lean burn combustion field. The phenomenon of high turbulence and lean burn was elucidated. Based on the result, an ignition technology that allows for stable flame was developed. In this manner, super-lean burn—low temperature combustion with low energy loss—was achieved, successfully verifying the improvement in thermal efficiency.

2. Research and development on improving the efficiency of diesel combustion

- Combustion concept: "High-speed space combustion"

- Challenges in realizing the concept: Due to flame retention and afterburning near the wall of the combustion chamber in an engine, energy loss (cooling loss) may occur or combustion efficiency of combustion energy to work may decrease.

Implementation content and results: Through detailed analyses and experiments on the development of fuel spray technology and the distribution of fuel concentration, the relationship between the principle of fuel spray and flame formation was elucidated. The cause of afterburning was identified. Based on these results, a fuel spray technology that disperses optimally while incorporating air was developed. Thus, high-speed space combustion that distances flames away from the wall was realized and an improvement of thermal efficiency was successfully verified.

3. Research on minimization of loss (in common to gasoline and diesel combustion)

- 3-1. Research on reducing mechanical friction loss

- Outline of research and development: Development of a highly durable low friction layer consisting of solid lubricant and soft metal and its surface modification technology added low friction function to the sliding surface of the engine, and verified 55% reduction in the mechanical friction loss.

- 3-2. Research on effective use of exhaust energy (improved efficiency of turbo supercharging)

- Outline of research and development: Cascade and flow path were newly designed based on flow analyses, and a turbo supercharger system that takes heat transfer and friction in bearing into consideration was constructed. The maximum improvement in efficiency of 69%, 10 points above the efficiency of commercial turbosupercharger, was verified.

- 3-3. Research on effective use of exhaust energy (improved efficiency of thermoelectric conversion system)

- Outline of research and development: New element and module were developed to expand the range of temperature for power generation to mid-and-low temperature ranges. Including the heat exchange system with exhaust heat, maximum thermal efficiency equivalent of 1.3% was verified.

Outline of the technology that has achieved the maximum net thermal efficiency of over 50%.

The project participating organizations are across Japan, totaling 1,300 over five years.

To combine strength of diverse members, a research base (open laboratory), freely available to members of both industry and academia, was established.

Future outlook

Cutting edge knowledge and technology gained from this project are incorporated into research, development, and design in competitive areas of companies, and are combined with technologies to secure performance, reliability, and durability as marketable passenger vehicles and mass production techniques , which are needed to lead to commercialization.

In addition, industries and academia are working through industry-academia collaboration to further develop each result in order to start and sustain future R&D without delay from the end of this project.

Other results

The present project has also achieved the following results, in addition to the above.

- Development of a 3D combustion analysis software – HINOCA– for automotive engine cylinder

Scientifically and practically superior and advanced combustion analysis software that is able to analyze flow and combustion field with high precision - Development of a model-based control system of diesel engines – RAICA

A new control system to maintain ideal combustion even in environments with transients or disturbances

- Environment and Energy

- Research Results

- Japanese