Research Results

Heat resistance and high power conversion efficiency

Organic solar cells that can be washed and ironedFY2019

- Kenjiro Fukuda(Senior Research Scientist, RIKEN Thin-Film Device Laboratory)

- PRESTO

- Innovative Nano-electronics through Interdisciplinary Collaboration among Material, Device and System Layers “Fabrication of fully-printed, substrate-free organic integrated circuits using nanometer-thick polymer dielectric layer” Researcher (2014-2017)

Thickness of only 3 μm

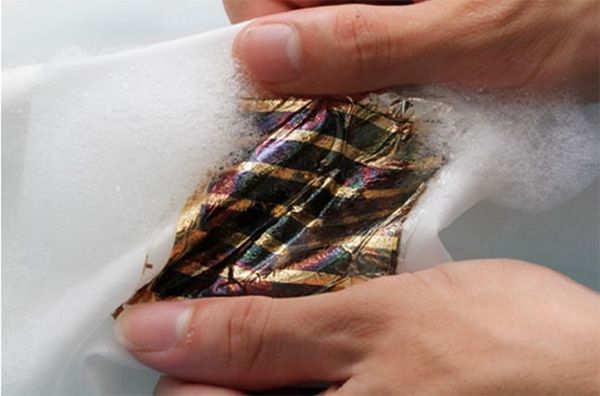

As a pioneering and full-time researcher at RIKEN, Dr. Kenjiro Fukuda and others developed an ultra-thin organic solar cell with high-power conversion efficiency with successfully applied flexibility, water resistance, and heat resistance to the point that it can be washed and ironed. This ultra-flexible organic solar cell has a thickness of only 3 μm, including the substarte and the passivation layers, and remains functional even when bent or crumpled. Furthermore, it has been confirmed that it is functional when stored in the open air or water for long-term.

In recent years, by combining energy harvesting technology* and a sensor, small and light-weight sensors are being developed. Especially, if a wearable sensor that could be attached to clothing is further developed, biological information such as electrocardiogram and body temperature could be continuously measured, leading to early discovery of diseases such as cerebral infarction and cold.

For developing such a sensor, power supply is important. Flexible organic solar cell that is able to provide a large amount of power is attracting attention as a strong candidate for a power supply for wearable sensors.

*A technology that extracts a small amount of energy from the environment such as light, vibration, and heat.

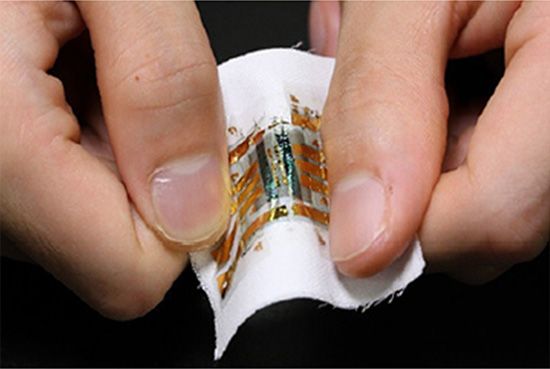

Figure 1. A white shirt with an ultra-thin organic solar cell element (with a thickness of 3 μm) is immersed in detergent water and washed.

Drastically improved water resistance while maintaining flexibility

The point of development is the development of a new semiconductor polymer* that balances high environmental stability and high power conversion efficiency. A film with good crystallinity can be formed, and the decrease in conductivity due to heating can be suppressed (Figure 2). The technology that forms this ultra-thin film on a polymer substrate was the key to achieving this ultra-thin organic solar cell. Furthermore, by sandwiching the ultra-thin organic solar cell from both sides with pre-stretched rubber, water resistance was drastically improved while maintaining the flexibility.

Since it is difficult to satisfy three conditions—power conversion efficiency (efficiency of converting solar energy to electric power), flexibility, and water resistance—simultaneously, there have not been organic solar cells that could be attached to clothing and washed. When using an especially thin film, it is difficult to secure smoothness of the surface, and the state having non-permeability of gas drastically decreases. Therefore, it was difficult to achieve high performance and long-term stable operation, limiting to realize the power supply for wearable sensors.

*A polymer material with semiconductor property (polymerized organic compound). It absorbs visible light, and dissolves in an organic solvent. Thus, it is applied to organic devices such as organic solar cells as semiconductors that can be painted.

Figure 2. (Left) New semiconductor polymer and (right) conventional material

The notable characteristic of the new semiconductor polymer is the linear structure (red box). This achieves high crystallinity and heat resistance.

Power conversion efficiency of 10% with high stability

The present ultra-thin organic solar cells fabricated this time presented high energy conversion efficiency in the state of being peeled off from the glass support base. Our research group had improved power conversion efficiency to 7.9% with the ultra-thin organic solar cells, but this study achieved the maximum power conversion efficiency of 10%.

In terms of stability, the decline in power conversion efficiency was limited to 20% even after storing in open air for 80 days. Comparing to the conventional decrease in power conversion efficiency by 50% after 700 hours, it has achieved drastically superior atmospheric stability. Even after being stored in water for 120 minutes, the decline in power conversion efficiency was only about 5%. When water was dripped onto the device for a certain amount of time while repeatedly stretching by about 50%, the initial power conversion efficiency of 80% was maintained.

Furthermore, power conversion efficiency barely changed even after being placed on a hot plate that was heated to 100°C. Using this high degree of heat resistance, we succeeded in pasting on cloth by using the hot-melt adhesive*, which is a typical method used in clothing manufacturing. There was little change or deterioration in the properties of solar cells before and after the adhesion.

*An adhesion method that uses an adhesive that melts under heat.

Figure 3. Current and voltage properties of the ultra-thin organic solar cells

It was confirmed that a glass base (black) and the ultra-thin organic solar cells (red) had comparable properties. The maximum of 10% power conversion efficiency was achieved.

Figure 4. Heat resistance of the ultra-thin organic solar cell.

While there was no deterioration in the properties of the new semiconductor polymer when heated to 100°C, the power conversion efficiency of the conventional material decreased by 20% when heated to 100°C.

Supporting the future of wearable devices

The flexible and washable ultra-thin organic solar cells that were realized in this study attract attention as a long-term stable power supply toward wearable devices and e-textiles*. By utilizing its high heat resistance, it could be applied as a flexible power supply withstanding environments with heating. When the study progresses, it may contribute to achieving power supply that works stably in high-temperature high-humidity environment such as inside of a vehicle.

Results of the present study were published in a British scientific journal, ‘Nature Energy’ and in a US scientific journal, “Proceedings of the National Academy of Sciences of the United States of America”, and were reported in many newspapers and televisions in Japan. There was a large response.

*Electronic devices such as sensors and microchips are embedded in clothing and fabric (textile) to create a textile material with new functions, such as information collection and remote control, that could not be achieved with regular fabric materials.

Figure 5. The ultra-thin organic solar cells attached to a textile using the hot-melt adhesion