Research Results

Reduction in carbon dioxide emissions

Power generation by combustion using ammoniaFY2019

- Hideaki Kobayashi(Professor, Institute of Fluid Science, Tohoku University)

- SIP

- Energy Carrier "Ammonia Direct Combustion" Principal Investigator

The world's first via gas turbine

Since ammonia does not emit carbon dioxide (CO2) when burned, by replacing the coal and natural gas currently used as the fuel for power generation with ammonia, a large-scale reduction in CO2 emission is anticipated. Traditionally, ammonia has been manufactured using fossil fuels as the raw material; however, in recent years, there have been attempts to manufacture ammonia using renewable energies such as solar power. If such a method can be put to practical use, ammonia could become a carbon-free fuel.

In "energy carrier," which is a topic in the "Cross-ministerial Strategic Innovation Promotion Program," (SIP) direct combustion of ammonia is one of the research and development areas. The research director, Professor Hideaki Kobayashi and his team members in AIST-FREA have developed the fundamental technology for direct combustion of ammonia, and achieved the world's first gas turbine power generation based on ammonia fuel in 2014. Furthermore, they succeeded in generating 2 MW large gas turbine power based on the fuel, in which 20% ammonia in lower heat value (LHV) is mixed in methane, in March 2018.

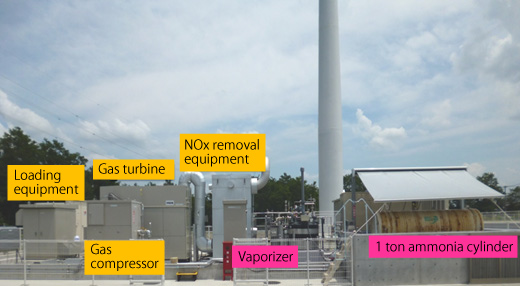

The micro gas turbine power generation equipment at The Fukushima Renewable Energy Institute, (FREA) of The National Institute of Advanced Industrial Science and Technology (AIST) (photograph provided by AIST).

Changes in fuel supply and power output in 100% ammonia combustion trial

Gas swirling stabilizes the flame

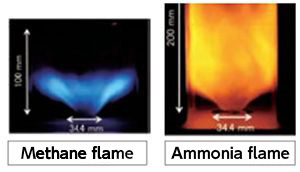

There are many challenges in developing power generation technology using ammonia as fuel. For example, compared to other hydrocarbon fuels such as methane, which is the main component of city gas, ammonia has an extremely narrow flame-holding range in which the flame is stabilized at a favorable condition. The burning velocity is extremely slow at 1/5th that of methane. Due to such issues, the flammability of ammonia is low, and ignition and flame-holding are difficult.

To solve these problems, Professor Kobayashi and others considered using a swirl burner* to rotate the air inside of a combustion chamber and controlling the flow of mixture of ammonia and air would stabilize combustion. When the size and pattern of swirling flows were changed by changing the rotational speed of the gas in the burner, the ammonia flame could be stabilized. Subsequently, by establishing a 3D numerical simulation method, they optimized the supply ratio and rate of ammonia and air. In this manner, the combustion condition, in which the generation of nitrogen oxide—a cause of acid rain and atmospheric pollution—and unburned ammonia are reduced, was theoretically verified.

In this study, they aim to elucidate the combustion mechanism of ammonia based on these previous achievements. They conducted tests under an environment according to the operation of an actual gas turbine power in pursuit of a practical combustion method.

*A burner that emits gas from a spiral gap for combustion.

Successful co-firing with coal thermal power

When ammonia is directly burned with the developed combustion technology, and a turbine is turned by the high-temperature high-pressure gas that is generated, it is possible for power to actually be generated. The world's first ammonia fuel power generation was realized in August 2014, using a gas turbine power device with a maximum output of 50 kW in AIST-FREA. When burned at 70% kerosene and 30% ammonia in LHV, stable power generation with an output of 21 kW could be maintained.

In September 2015, they successfully generated gas turbine power with methane-ammonia mixed gas, and 100% ammonia fuel. The generated power reached 41.8 kW in both cases, indicating that ammonia could be used as a fuel for thermal power. The gas turbine power has been enlarged, leading to 2 MW power output in March 2018 by IHI.

In recent years, along with gas turbine power, they are working on the development of coal thermal power as well. If a large amount of ammonia could be introduced to the coal thermal power plant, reduction in CO2 could be possible. Therefore, they conducted a test on co-firing of ammonia and pulverized coal, and succeeded in co-firing with 20% ammonia in LHV, which is the highest in the world. Now, practical use of the combustion technology that uses ammonia as the fuel for coal thermal power plants may be within reach.

Test facility for ammonia co-firing gas turbine (photograph provided by IHI)

Large-capacity combustion test facility (photograph provided by IHI)

Minimizing the production of nitrogen oxides

In the future, they aim to increase the combustion efficiency of ammonia gas turbines to the same level as gas turbines that use natural gas. At the same time, they aim to make improvements that minimize the generation of nitrogen oxides—the cause of acid rain and atmospheric pollution—during the combustion stage toward practical use of gas turbine power that uses ammonia as the fuel. They will also continue to work toward technological development and verification of ammonia application toward engines for transportation, and thermal use of industrial furnaces that use ammonia as the fuel.

There are other advantages of ammonia in addition to not emitting CO2. Presently, ammonia is widely used worldwide as fertilizer and chemical raw material, and its mass transportation by ship is well-established. In other words, it is possible to manufacture carbon-free ammonia overseas, and transport and store using existing technology.

Furthermore, denitration equipment, essential to thermal power plants, removes nitrogen oxide by using ammonia with a catalyst; thus, there is always an ammonia tank at thermal power plants, and workers are highly skilled in the handling of ammonia. There are few barriers to introducing ammonia as a fuel for thermal power, and its practical implementation in the near future is a realistic goal.

- Environment and Energy

- Research Results

- Japanese