Research Results

|

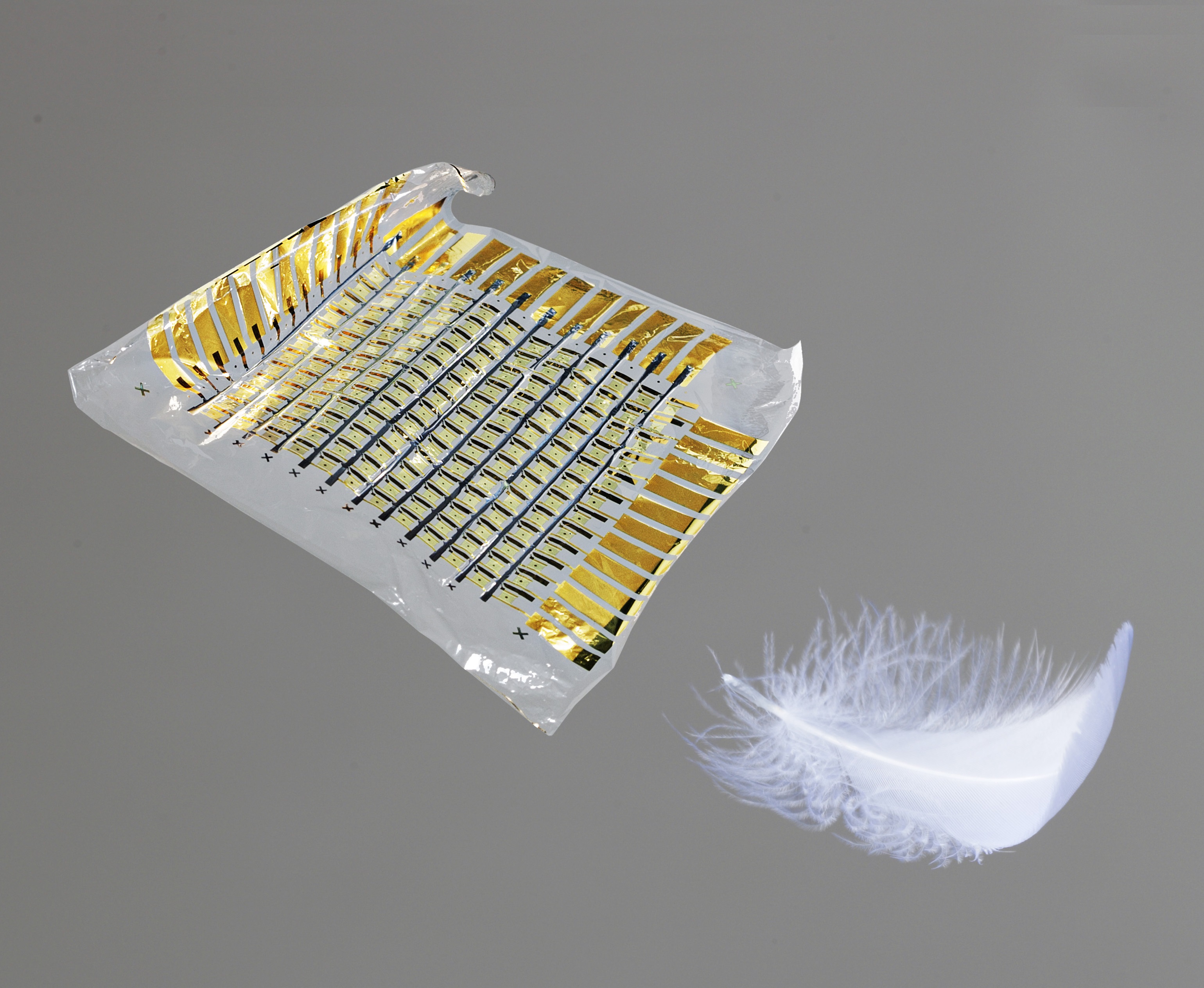

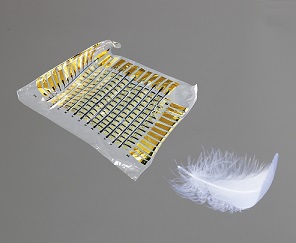

“Imperceptible electronics that are lighter than a feather”The world's lightest and thinnest flexible integrated circuits will produce stress-free wearable healthcare sensors The team has succeeded in developing the world's lightest (3 g/m2) and, simultaneously, the world's thinnest (2 µm) mechanically flexible integrated circuits and touch sensor system. This was possible because the team developed a novel technique to form a high-quality 19-nm-thick insulating layer on the rough surface of the 1.2-µm-thick polymeric film. Imperceptible electronics, namely, extremely thin, lightweight electronics whose presence cannot be perceived when worn, will open up a wide range of new applications in fields ranging from healthcare and biomedicine to welfare. |

“The World’s Lightest, Thinnest, Flexible Organic Light-Emitting Diodes (OLEDs) “ The team has succeeded in developing the world’s lightest (3 g/m2) and, simultaneously, the world’s thinnest (2 µm) mechanically flexible ultrathin PLEDs. The key to this success is the low temperature processing that enables OLEDs to be fabricated on rough 1-µm-thick polymeric film. Instead of using indium tin oxide (ITO) transparent electrode, the team has adopted a conductive polymer, which can be fabricated at low temperature with low-loss as an anode. These soft, ultrathin and ultralight OLEDs can be very useful as novel OLED lightings that are applied to any arbitrary surface and light sources for imperceptible healthcare sensors. |

|

“The World’s Thinnest, Lightest, Flexible Organic Photovoltaic Cells“ The team has succeeded in fabricating organic solar cells thinner than a thread of spider silk. The new devices can be wrapped firmly around a human hair and are lighter than autumn leaves. Thanks to ultrathin features, they exhibit the world’s largest photo-generated power per unit weight, which is 10 W/g. Solar cell fabrication is based on planar process technologies only, commonly employed in semiconductor industry. When adhered on conforming surfaces, the solar cells become stretch compatible withstanding tensile strains over 300%. Applications of the technology may arise wherever mass is a critical concern and span from small scale robots to health care and biomedical systems. |

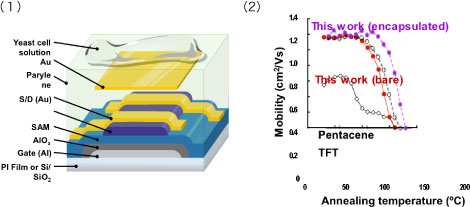

“The world’s first sterilizable flexible organic transistor” The team has succeeded in manufacturing on a polymeric film the world’s first flexible organic transistor that is robust enough under high temperature medical sterilization process. The key to realize heat resistant organic transistor is in the forming technique to form extraordinarily densely packed self-assembled monolayer (SAM), whose thickness is as small as 2 nm, on a polymeric film. This allows them to elevate substrate temperature up to 150°C without creating pinholes. It should be benefited more from applying this heat-resistant organic transistor to long term implantable devices, or to some medical devices such as a smart catheter. |

Ultra-lightweight Imperceptible Electronics

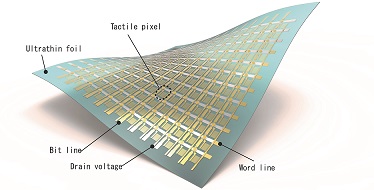

【Summary】Here we demonstrate featherweight, thin, flexible and virtually unbreakable electronic foils that can conform to any curvilinear and dynamic surface. These 2-µm-thick electronics feature a bend radius of 5 µm and can be crumpled like paper without breaking. Potential applications include medical devices, wearable health monitors, heat sensors, and displays.

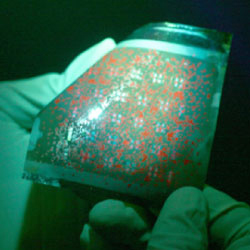

The world's lightest (3 g/m2) and thinnest (2 µm) high-performance organic transistor ICs were fabricated on ultrathin (1.2 µm) polyethylenenaphthalate (PEN) films, making them ultra-flexible and virtually unbreakable. These devices are 5 times thinner than plastic kitchen wrap and 30 times lighter than standard weight office paper. The organic transistor IC serves as the backplane to a prototype touch sensor system consisting of 144 (12 × 12) sensor cells arranged in an effective area of 4.8 × 4.8 cm2 with an inter-cell spacing of 4 mm. This soft sensor system can be applied to arbitrarily curved surfaces like human skin, and in the future may be able to continuously measure body temperature, blood pressure, and many other vital signs. Immersing the devices in physiological saline (with components that are the same as bodily fluids or sweat) for more than two weeks caused no obvious deterioration in the electrical properties. Additionally, when these devices are applied to a prestretched elastomer, they can be stretched up to 233% with only negligible changes in electrical and mechanical performance. ]

One of the developments which enabled the fabrication of these devices was a technique for forming the ultrathin insulating layer on a 1-µm-thick polymeric film with high surface roughness. This method allowed for room temperature deposition of 19 nm of aluminum oxide, with excellence surface adhesion and self-healing properties. These methods avoid high temperature and high-energy processes and are fully compatible with the processing requirements of ultrathin and conformable foil substrates.

【Paper】Martin Kaltenbrunner, Tsuyoshi Sekitani, Jonathan Reeder, Tomoyuki Yokota, Kazunori Kuribara, Takeyoshi Tokuhara, Michael Drack, Reinhard Schwoediauer, Ingrid Graz, Simona Bauer-Gogonea, Siegfried Bauer, and Takao Someya, “An ultra-lightweight design for imperceptible plastic electronics”, Nature 499, 458–463 (25 July 2013) doi:10.1038/nature12314.

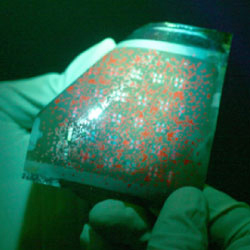

The world’s thinnest OLEDs

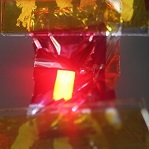

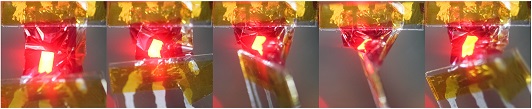

【Summary】Polymer based light emitting diodes only 2 µm thick are five times thinner than cling wrap and weight just 4 g/m2, that is 20-fold lighter than office paper. This research may lead to displays that you can flex, bend, and crumple like a tissue, made possible by the polymer LEDs because they are so thin.

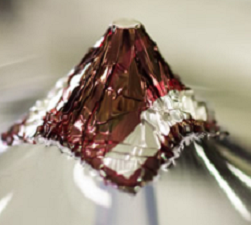

In an ongoing collaboration between the Johannes Kepler University in Linz, Austria, and the Someya-Sekitani Group at the University of Tokyo, we have now developed ultrathin (2 µm thick) polymer LEDs with unprecedented mechanical properties in terms of their flexibility and ability to be stretched. We used several luminescent polymers to create different colors of ultrathin PLEDs. Most interestingly, we developed a custom (synthesized in house) polymer with high quality red emission, suitable for RGB displays. The PLEDs have display compatible brightness as well (100 cd/m2), leaving them only a few steps away from product applications. Because they are so thin they are both extremely lightweight and flexible. They weigh only 4 g per square meter, and they can be crumpled like a tissue during operation.

【Paper】Matthew S. White, Martin Kaltenbrunner, Eric D. Głowacki, Kateryna Gutnichenko, Gerald Kettlgruber, Ingrid Graz, Safae Aazou, Christoph Ulbricht, Daniel A. M. Egbe, Matei C. Miron, Zoltan Major, Markus C. Scharber, Tsuyoshi Sekitani, Takao Someya, Siegfried Bauer, and Niyazi Serdar Sariciftci, ”Ultrathin, highly flexible, and stretch-compatible PLEDs”, Nature Photonics (28 July 2013) doi:10.1038/nphoton.2013.188.

Ultrathin PLED operated as free-standing foil. Because our PLEDs are so thin, they can be crumpled like a piece of tissue during operation and do not break.

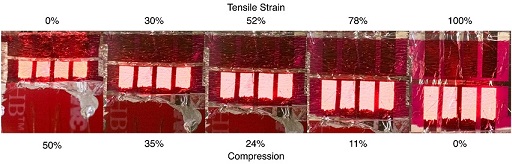

Ultrathin PLEDs become stretchable when they are laminated to a pre-stretched elastomeric band. When the band is relaxed, out of plane wrinkles and folds with bending radii smaller than 10 µm form. Like this, PLEDs can be stretched repeatedly to twice their length without damage.

Ultrathin and lightweight organic solar cells with high flexibility

【Summary】We have developed the world’s thinnest and lightest solar cells that are highly flexible and become stretchable to more than 300% when laminated to a rubber band. The solar cells are fabricated on ultrathin plastic films with a thickness of only 1.4um, weigh only 4g/m2 and therefore deliver a record-high specific power of 10W/g.

Organic photovoltaic (OPV) cells are highly promising devices. Primary benefits of OPV cells are low cost, low weight, flexibility and compatibility with reel-to-reel processing for high volume production. In this work, we show that solar cells can be fabricated on ultrathin substrates without degrading the power conversion efficiency as compared to their glass-substrate counterparts.

We have developed a method for fabricating ultrathin, lightweight, flexible and compliant OPV devices constructed on only 1.4-µm-thick polyethylene terephthalate (PET) substrates. We have obtained solar cells with 4.2% power conversion efficiency that weigh as little as 4g/m2. This results in an unprecedented specific power of 10W/g, the highest value achieved for all solar cell technologies to date. Their high flexibility allows them to be wrapped even around a human hair and reversibly attain tensile strains of more than 300% when placed on an elastomeric support.

The extremely low weight and high specific power output is of advantage for mobile applications, e.g. a power supply for stress free healthcare devices or remote sensing applications.

【Paper】Martin Kaltenbrunner, Matthew S. White, Eric D. Głowacki, Tsuyoshi Sekitani, Takao Someya, Niyazi Serdar Sariciftci, and Siegfried Bauer, “Ultrathin and lightweight organic solar cells with high flexibility”, Nature Communications,3, Article number: 770 (03 April 2012) doi:10.1038/ncomms1772.

“The world’s first sterilizable flexible organic transistor”

【Summary】We have proofed high thermal stable organic transistors which works well even after 150-degreeC sterilization process. Those organic transistors are protected by metal/polymer hybrid encapsulation layers. In addition, we have realized low-voltage operation with high field-effect mobility using dinaphtho-thieno-thiophene(DNTT) as organic semiconductor and self-assembled monolayer(SAM) as a part of gatedielectrics.

We have improved thermal stability of organic thin-film transistors by metal/polymer hybrid encapsulation layer (Fig.1), and finally, these organic transistors withstand heat sterilization up to 150 degree C. These organic transistors consist of DNTT for organic semiconductor and AlOx/SAM hybrid layer for gatedielectric. Mobility of organic transistor is 1.2 cm2/Vs with operation voltage of 2V(Fig. 2).

Thermal stability of SAM layer have been discovered by near edge X-ray absorption fine structure. It is said that arrangement of SAM is thermally stable up to 200 degree C although its tilt angle changes from 14 degree to 18 degree by heating. At the same time, dichroic ratio of SAM layer decrease form 0.60 to 0.52, but it have been still high.

【Paper】Kazunori Kuribara, He Wang, Naoya Uchiyama, Kenjiro Fukuda, Tomoyuki Yokota, Ute Zschieschang, Cherno Jaye, Daniel Fischer, Hagen Klauk, Tatsuya Yamamoto, Kazuo Takimiya, Masaaki Ikeda, Hirokazu Kuwabara, Tsuyoshi Sekitani, Yueh-Lin Loo, and Takao Someya, “Organic transistors with high thermal stability for medical applications”, Nature Communications 3, Article number: 723 (06 March 2012).