About Research Domains

- JST HOME

- SM4I HOME

- Research Domains Top

- MI Top

- Engineering Polymers MI

[Main Text]

About Research Domains

Engineering Polymers MI

(D70・D71・D72・D74・D75)

Concept and Approach

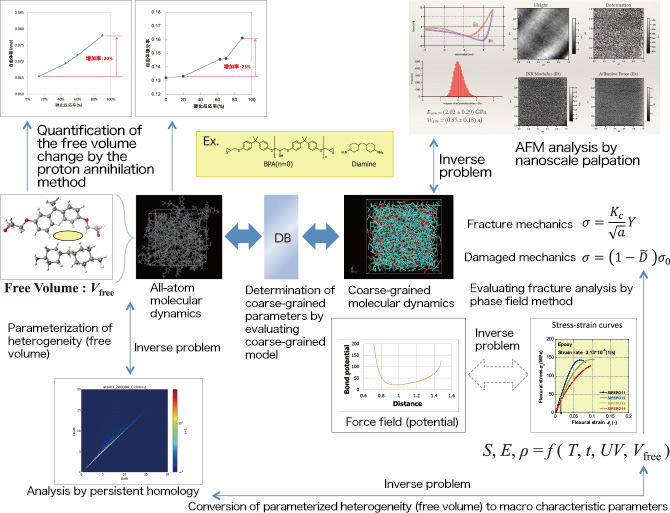

In Materials Integration for polymer materials, we are aiming to establish a database structure that can uniformly understand the phenomena and properties occurring in the wide range of length and time scales, or from the molecules at the nanometer (nm) level to large bulk materials and large structures at the meter (m) level in length scales, and from the short phenomena in picoseconds (ps) to the longer structural behavior for decades in time scale. We provide tools to support to solve issues at the time of research by making full use of knowledge of science and technology such as analytical and empirical forms, instead of relying solely on simulation. In the future, we will aim to make it a system comparable to polymer handbooks and polymer textbooks. We have adopted a newly introduced mathematical database to enable data processing among plural length scales and time scales. We use parameters with a great number of physical meanings for data processing. We hope that this makes it possible to solve pseudo-inversion problems, which computerize inversely process conditions and structural optimization from the performance of the structural materials.

Unit Structure and Role

The team members in Materials Integration for polymer materials are organized, under the leadership of Program Director, Prof. Teruo Kishi, by researchers adopted on individual themes that were not related to each other, based on the subjects of the performance of polymer materials for aircraft. After establishing research subjects, collaboration of research items and re-recruiting researchers, we have reached the current organization. It is organized for setting the research themes and solving the problems towards one goal with the potential of researchers in different field. We fully incorporate the needs of companies for specific subjects so that it is easy for them to integrate with the system developed when they incorporate their own databases or introduce new technology fields. It is also easy for many companies to use the accomplishments in Materials Integration.

Research and Development of Polymeric Materials MI

In order to clarify the relationship between molecular structures and mechanical properties of the cured resin, , we prepared epoxy cured product at first by typical epoxy reactions. The properties of the prepared product are analyzed by the following methods – mechanical property measurements, free volume measurement by positron annihilation method, nano-palpation atomic force microscopy (AFM) analysis and molecular dynamics analysis.

The obtained data were analyzed by the persistent homology analysis to evaluate inhomogeneity of the prepared products mathematically to create database for the application of solving inverse problems. The data from the mechanical properties measurements are used to evaluate the influence of the reaction rate on the mechanical properties. The tendency of free volumes to increase with the conversion rate was quantitatively confirmed by the positron annihilation method. We have obtained the outcomes agreeing well with the analysis result by the total atomic molecular dynamics method. The micro inhomogeneity expressed in terms of parameters is linked to the macro specific parameters of dynamical systems of fracture mechanics or damage mechanics of structural materials. Thus, we aim to develop the polymer materials integration (MI) system consisting of practical calculation modules that can correlate multi scales of space and time mutually. In addition to conventional way to study polymers, a new approach from the different point of view by the new members with different background of science and technology. Thus, our research and development are evolving into much higher level and novel polymer MI studies. For instance, we have succeeded in combining different technical elements by the use of mathematical approaches in order to select the components of polymer materials.

List of R&D Projects and Units

| Category | No. | R&D Project | Research Unit | Unit Leader |

|---|---|---|---|---|

| Metal MI | D61 | Materials Integration | Development of Microstructure Prediction System | ◎☆Toshihiko Koseki (UTokyo) |

| D62 | Development of Performance Prediction System | Manabu Enoki (UTokyo) | ||

| D63 | Development of a System for Data Assimilation and Machine Learning | Junya Inoue (UTokyo) | ||

| D64 | Development of Materials Integration System | ☆Makoto Watanabe (NIMS) | ||

| D65 | Development of Simulation Technique for Performance Assurance of Weld Joints | ☆Akio Hirose(Osaka U.) | ||

| D67 | Fundamental Research Focusing on Interface for overcoming Unsolved issues in Structural Materials | ☆Kaneaki Tsuzaki (Kyushu U.) | ||

| Innovative Measurement | D66 | Innovative Measurement and Analysis for Structural Materials | ☆Masataka Ohkubo (AIST) | |

| Ceramics Coating MI | D68 | Development of Simulation for Mass Transfer at High Temperature and Time Dependent Behavior of Microstructure | Hideaki Matsubara (Tohoku U.) | |

| D69 | Development of Computational Tools to Predict Time Dependent Phenomena in Structural Materials | Tetsuo Mohri (Tohoku U.) | ||

| D73 | Establishment of Domestic Technology Base for Computational Thermodynamics for Development of Advanced Structural Materials | Kazuhisa Shobu (AIST) | ||

| Engineering Polymers MI | D70 | Development of Prediction Tools for Long-term Properties of High Performance Engineering Plastics | Takashi Kuriyama (Yamagata U.) | |

| D71 | Development of Practical Optimal Design and Comprehensive Evaluation Support Tool for Advanced Structural Polymer Materials | Shin-etsu Fujimoto (Nippon Steel & Sumikin Chemical) | ||

| D72 | Mathematical Approach Toward Materials Integration and its Applications | Yasumasa Nishiura (Tohoku U.) | ||

| D74 | Performance Prediction for Polymers by Nonlinear Analysis | Kazuyuki Shizawa (Keio U.) | ||

| D75 | Atomic / Molecular-level Approaches for Designing Novel Polymeric Materials | Takefumi Yamashita (UTokyo) | ||

◎:Co-Director of Research Domain ☆:Co-Manager