About Research Domains

- JST HOME

- SM4I HOME

- Research Domains Top

- Materials Integration (MI)

[Main Text]

About Research Domains

Materials Integration

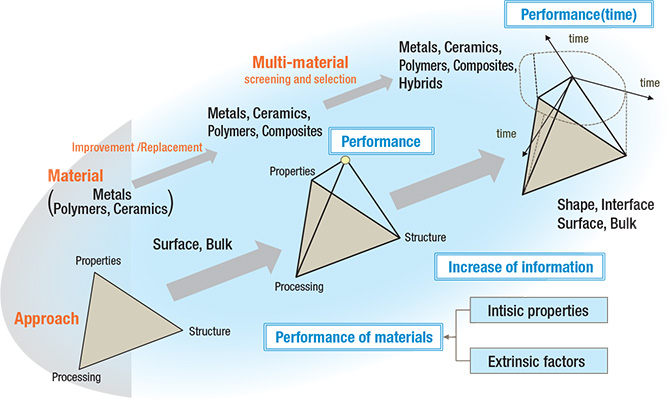

In addition to conventional material research of process, structure and properties, we introduce the performance in use and combine it with the basic and fundamental technology which is necessary for realizing and solving required performance.

We also hope that it is to be useful in the era of multi-material surpassing the barrier among materials.

Materials Integration (MI) System that shortens the time for research and development of materials

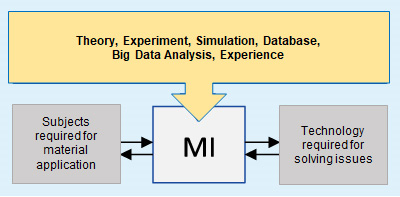

Materials Integration (MI) is defined as the comprehensive tool of material technology aiming to support research and development of materials from the engineering point of view by utilizing not only the accomplishments of materials science, but also all areas of science and technology, such as theories, experiments, analyses, simulations and databases.

The target is the performance of all kinds of materials and components, such as metal materials, polymer materials, ceramics materials, composites, in the actual environment of use.

The purpose of research and development of Materials Integration is to provide a tool that can contribute to shorten the time for research and development of materials and composites.

With this tool, you can learn the relevance at various levels of materials, structure, property and performance, and we can also use it for the research and development.

This relevance can be obtained from any level of dimension or time and in any order.

For example, it is also possible to obtain solutions to optimize the flow from performance to material process in a short time, but not the flow from material process to performance.

At this time, it becomes possible to know the temporal change in its influence by knowing the influence of the environment of use, which takes a long time for evaluation and analysis. And then it can be useful for material development.

It is important in the future era of multi-material to obtain the optimum answer surpassing the barrier among materials. The system also requires flexibility that corporate users can add the necessary databases for their own use to utilize the whole system.

We provide you a new knowledge and the way how to use the knowledge by Materials Integration.

It is currently expected to be a tool that everyone can easily use the knowledge of the most advanced science technology.

Materials Integration System aims to accumulate (integrate) new knowledge which cannot be obtained by conventional technology

Characteristics of Materials Integration (MI) for Effective Utilization of Science and Technology Accomplishment

The research of Materials Integration and development in SIP Structural Materials for Innovation is a combination of all kinds of knowledge of materials related technology, such as theory, experiment, experience, know-how and database etc. as necessary. It is not a simple simulation by using a computer, and the system aims to conduct materials research and development efficiently making full use of accomplishment and knowledge of science and technology in the world. It makes it possible to overcome difficult subjects in the current materials science, such as optimizing process conditions from required performance.

In this program, we are aiming to provide Materials Integration system for material development with a new concept to contribute to the innovation of industrial products for metallic materials, polymer materials and ceramics materials (coatings).

Implementation of Materials Performance

It is a big feature to deal with the performance from the point of materials users. There are issues such as fatigue, creep and corrosion which are important as the performance of structural materials. All the issues are time dependent premising on long time of use.

In research and development on the premise of long-term use, it is necessary to know the change in the material performance under the environment of use.

If you can predict performance quickly without relying on know-how or experiences in the research and development of materials, you can shorten the time required for research and development.

Shortening Research and Development Time / Greater Efficiency

It is an important research issue to create a mechanism to utilize effectively tremendous amount of accomplishments and know-how for theories and experiments that have ever been published and disclosed. It will enable us to integrate the cutting-edge accomplishments of science and technology in the different fields.

Effective Utilization of Advanced Science and Technology

It is an important research subject to create a system to utilize the results effectively and know-how of huge number of theories and experiments that have been published and disclosed.

The MI system enables active collaboration and integration of the advanced science and technology in different fields.

Computer Science and Network Use

In addition to the conventional methods for research and development of materials, we can also provide integrated skills for development of material technology with new concept of acquisition and utilization of stored data unused and computer science to overview the big data and database.

Future Development and Role

Irrespective of the types of materials, we can overview the technological areas of specialty to solve problems. It will be expected to be a useful tool for more powerful materials research and development by integrating the Internet of Things (IoT) and Artificial Intelligence (AI) in the future. Materials Integration aims to provide tools to support material development with new concepts of Integration of science and technology.

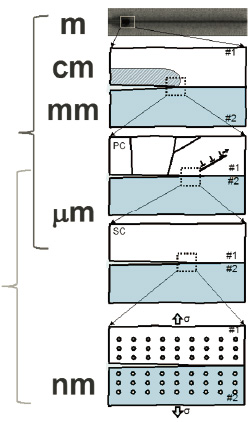

A case example of MI model of bonding and adhesion of interfaces

In treating the mechanical properties of materials, there are several theories and simulation techniques ranging from the nanometer level to the meter level (practical order). You can expect to obtain the most physically meaningful characteristics on each scale because there is a limitation for the range of one scale that can be dealt with.

For example, in a model of peeling off on the interface, the fracture energy obtained from the nm model is about 1/10~1/100 of the value obtained from the model on the order of the cm to m order.

To account for this difference, it is important to deal with deformations in the μm to mm order. It is necessary to understand that there is the best method for the phenomenon for each targeted dimension and time scale regardless of theory, experiment or simulation, in order to understand the behavior of the materials uniformly from the atom / molecule level to the m level of materials used as structure. It is also important to consider the mutual relationship paying attention to the mechanical performance depending on the defects size present in the material and the macro dynamic state acting on the material at this time.

List of R&D Projects and Units

| Category | No. | R&D Project | Research Unit | Unit Leader |

|---|---|---|---|---|

| Metal MI | D61 | Materials Integration | Development of Microstructure Prediction System | ◎☆Toshihiko Koseki (UTokyo) |

| D62 | Development of Performance Prediction System | ◎Manabu Enoki (UTokyo) | ||

| D63 | Development of a System for Data Assimilation and Machine Learning | Junya Inoue (UTokyo) | ||

| D64 | Development of Materials Integration System | ☆Makoto Watanabe (NIMS) | ||

| D65 | Development of Simulation Technique for Performance Assurance of Weld Joints | ☆Akio Hirose(Osaka U.) | ||

| D67 | Fundamental Research Focusing on Interface for overcoming Unsolved issues in Structural Materials | ☆Kaneaki Tsuzaki (Kyushu U.) | ||

| Innovative Measurement | D66 | Innovative Measurement and Analysis for Structural Materials | ☆Masataka Ohkubo (AIST) | |

| Ceramics Coating MI | D68 | Development of Simulation for Mass Transfer at High Temperature and Time Dependent Behavior of Microstructure | Hideaki Matsubara (Tohoku U.) | |

| D69 | Development of Computational Tools to Predict Time Dependent Phenomena in Structural Materials | Tetsuo Mohri (Tohoku U.) | ||

| D73 | Establishment of Domestic Technology Base for Computational Thermodynamics for Development of Advanced Structural Materials | Kazuhisa Shobu (AIST) | ||

| Engineering Polymers MI | D70 | Development of Prediction Tools for Long-term Properties of High Performance Engineering Plastics | Takashi Kuriyama (Yamagata U.) | |

| D71 | Development of Practical Optimal Design and Comprehensive Evaluation Support Tool for Advanced Structural Polymer Materials | Shin-etsu Fujimoto (Nippon Steel & Sumikin Chemical) | ||

| D72 | Mathematical Approach Toward Materials Integration and its Applications | Yasumasa Nishiura (Tohoku U.) | ||

| D74 | Performance Prediction for Polymers by Nonlinear Analysis | Kazuyuki Shizawa (Keio U.) | ||

| D75 | Atomic / Molecular-level Approaches for Designing Novel Polymeric Materials | Takefumi Yamashita (UTokyo) | ||

◎:Co-Director of Research Domain ☆:Co-Manager