Takane Suzuki

1987 Joined Kojima Industries Corporation

2010 – present Head of Development and Director, Kojima Industries Corporation

2014 – ImPACT Program Manager (Effort: 100%)

Over 30 years of experience in R&D and process development, with a consistent focus on advanced projects based on pioneering technology trends and global needs. Extensive experience in R&D management, with a track record of successful cross‐organizational integration of capabilities,, including production capabilities from Kojima Industries, state‐of‐the‐art elemental technologies from academia, and processing technologies etc. from small and medium‐sized specialty companies. Key contributor in Kojima Industries receipt of the Okochi Memorial Production Prize, the highest award given to production technology in Japan.

Overview

Disruptive Innovation

Keys to breakthrough

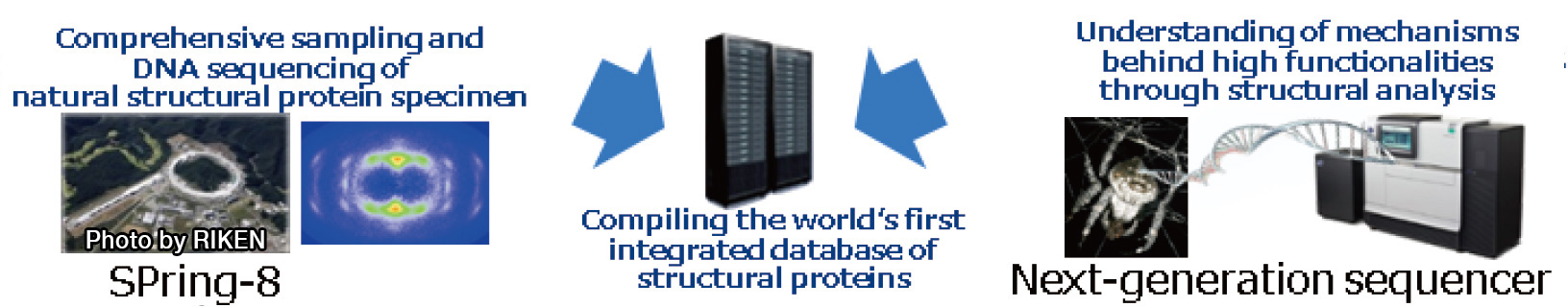

- The search space for molecular designs balancing “super-high function” with “productivity through recombinant fermentation” is immense, rendering it unrealistic to identify optimum designs through a simple trial & error approach.

→ State-of-the-art higher-order structural analysis will be used to understand the mechanisms behind the high functionalities, and comprehensive sampling and DNA sequencing of natural structural protein specimen will be conducted in order verify hypotheses. Obtained knowledge will be integrated into a database to efficiently narrow down the molecular design candidates to a number for which experimental verification is realistically possible.

The Challenges for the PM and the Impact of Success

Overview and background

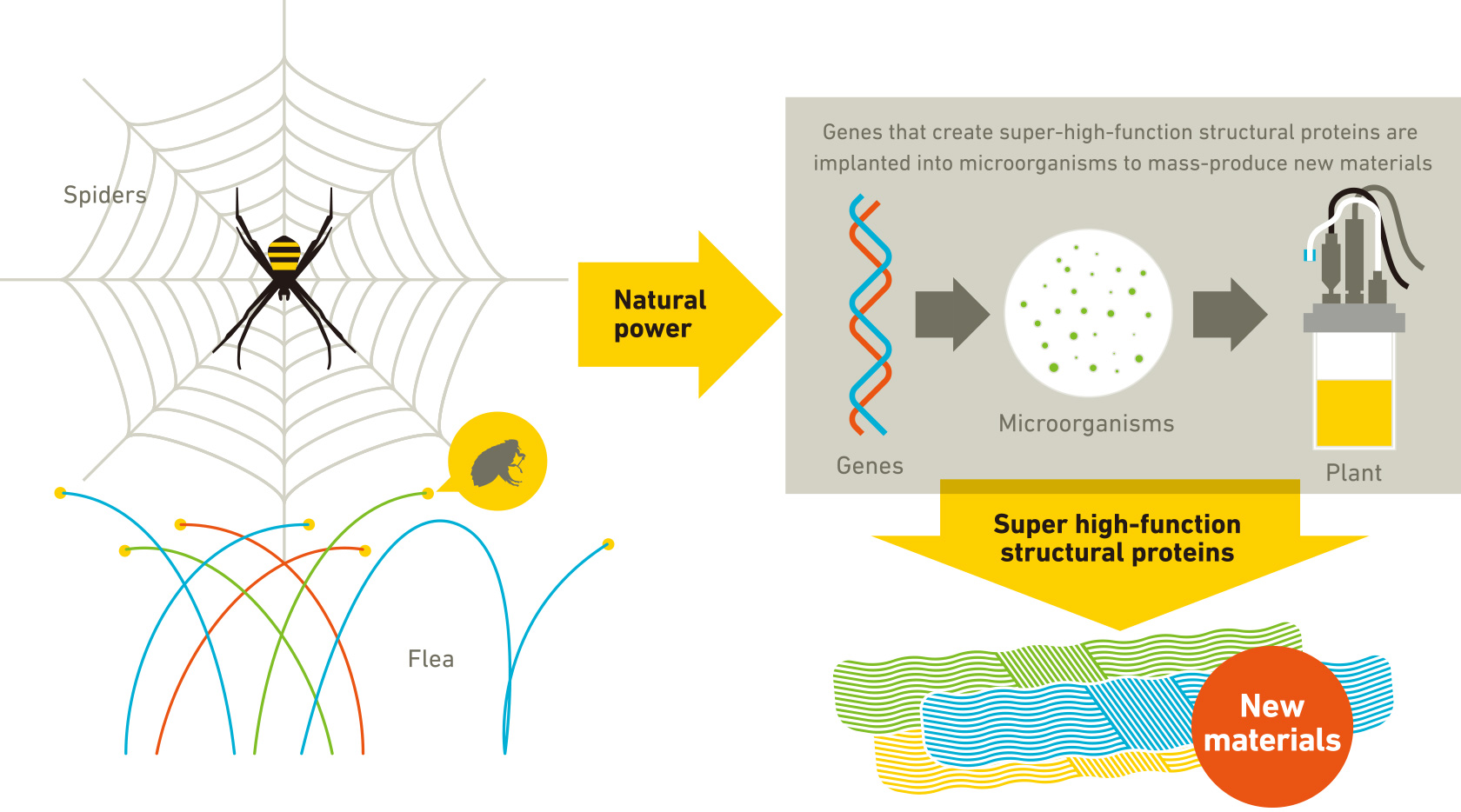

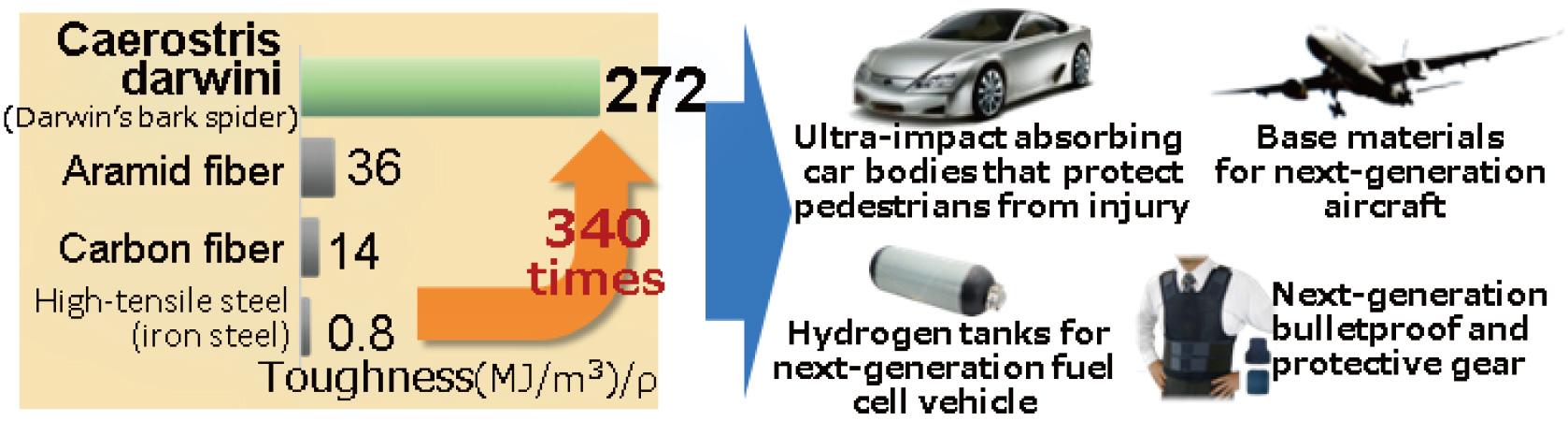

- Structural proteins exhibit extreme properties that can outperform conventional industrial materials. For example, spider silk has toughness per weight that is 340 times that of steel. Such materials have enormous potential to become a next generation basic material, and could enable industrial products that are not dependent on exhaustible resources such as oil. However, industrial application of these materials is yet to be started because there are several challenging technical barriers that need to be overcome before commercial production.

→ Development of structural proteins as a basic industrial material can greatly benefit Japan, which is currently dependent on import of natural resources as basic industrial materials. Maintaining initiative in this new industry can significantly contribute to Japanʼs future industrial competitiveness.

Impact on industry and society in the event of achievement

- Liberation of industry from dependence on exhaustible resources, and development of next-generation materials with extraordinary properties (balancing lightness and toughness at an extreme dimension), will enable the future product designs to balance environmental considerations with super-high functionalities.

Scenario for Success and Achievement Targets

Method of resolution for success (Approach)

- Japanʼs world-class higher-order structural analysis technologies, CS/IT, genetic engineering, synthetic biology, materials science, production technologies, etc. will be brought together to break through the technical barriers toward development of the structural protein material industry.

Management strategies

- Establish an ultra-multidisciplinary research & development organization to promote efficient and effective joint research & development that allows researchers to complement one another's technologies through feedback cycles.

- Establish an organization for integrated intellectual property management to promote open innovation to increase dissemination and competitiveness of the industry as a whole, to promote standardization and normalization for related technologies and packaging of patent groups, and to draft intellectual property strategies relating to the core technologies to enable Japanese companies to firmly seize the initiative in the industry.

Achievement targets

- Obtain evidence that annual production of protein materials at a scale of tens of thousands of tons at a industrially competitive cost is possible.

- Create materials and prototype product applications that demonstrate extreme toughness exceeding the maximum toughness of natural materials (strength 1.6 GPa, toughness 354 MJ/m3, Darwinʼs Bark Spider dragline silk)

Risks

- It will be essential to establish an exceptional R&D execution team that is not bound by existing concepts in order to break through technical barriers that have not previously been overcome by humanity.

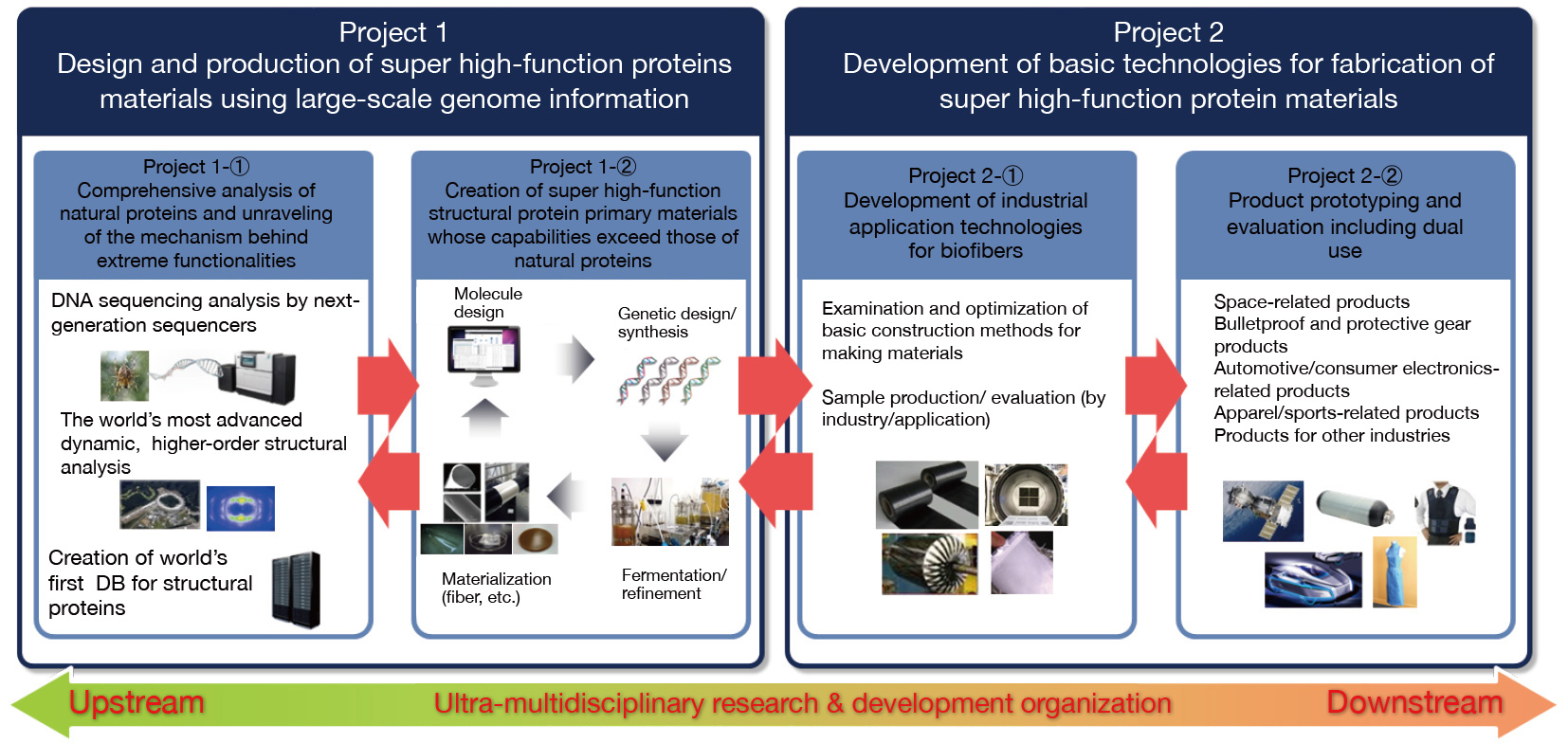

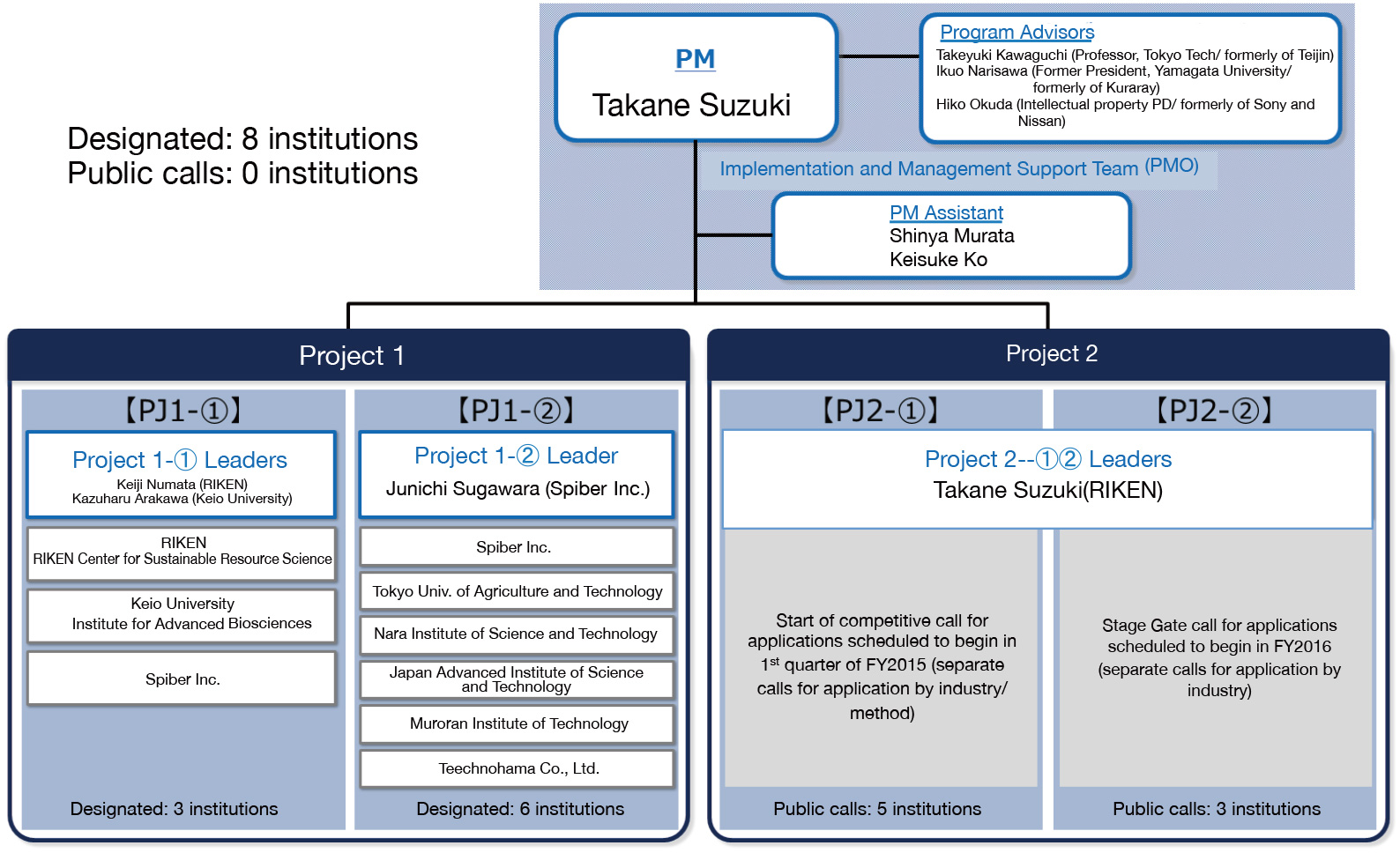

Overall R&D Program Structure Created by the PM

- Key success factor is the efficient prototyping and demonstration of new structural protein materials (Project 1‐(2)), based on input from research in the upstream gene analysis area (Project 1‐(1)) and the feedback from the downstream fabrication technologies (Project 2)

→It is critical that the entire end to end process of Project 1‐(2) be executed at a single research center that can efficiently implement cross‐process improvements.

Implementation Structure as Assembled by the PM

Keys of the implementation structure

- Selection of domain leaders possessing advanced technical research capabilities and high‐ level management capabilities. (selected top next generation talent from academia and the corporate world as leaders)

Approach to selection of institutions

- Project 1-(1): Institutions were nominated from academia and companies, based on world class knowledge and achievements in higher‐order structural analysis technologies, CS/IT, genetic engineering and synthetic biology, as well as high‐level research & development execution capabilities.

- Project 1-(2): Spiber Inc. was nominated as the core research organization. Spiber has the world’s largest structural protein material production facilities, and at present it is the only organization in the world that can perform the entire process, from molecular design of structural protein through raw material production, fiber creation, prototyping and evaluation within a single institution.

- Project 2-(1)(2): Following an open bidding process for the selection of academic institutions / companies with high manufacturing technology capabilities and development execution capabilities, an exit strategies team that combines these attributes with the ability to produce results in terms of commercial application and business development will be organized.

Organization

ImPACT: Impulsing Paradigm Change through Disruptive Technologies Program

ImPACT Program Manager

Takane Suzuki

Shinya Murata

Keisuke Ushiro