- JST Home

- /

- Strategic Basic Research Programs

- /

ERATO

ERATO- /

- Research Area/Projects/

- Completed/

- HAYASHI Ultra-Fine Particle

HAYASHI Ultra-Fine Particle

Research Director: Dr. Chikara Hayashi

(Chairman, ULVAC Corporation)

Research Term: 1981-1986

In this project, ultra-fine particles were produced for the purpose of clarifying the mechanism of nucleation and growth. The physical, chemical and biological properties of ultra-fine particles as well as crystalographic, electromagnetic, optical, thermal, and catalytic properties were also investigated. Studies were advanced in order to develop techniques for controlling particle size and composition as well as applying unique properties.

Research Results

Spraying process of ultra-fine particles: Ultra-fine particles of nickel and titanium nitride, or iron and silver were evenly mixed and compacted by spraying while successfully producing thin films of ultra-fine particles, enabling the manufacturing of various alloys and composite materials which have unconventional properties.

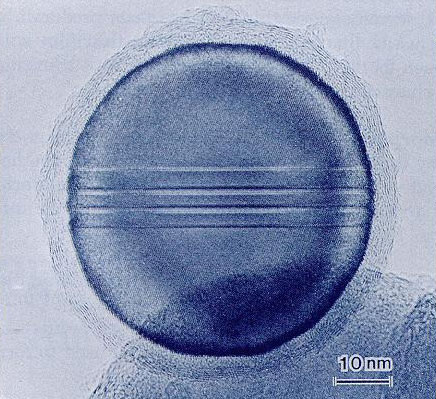

Manufacturing of ceramic ultra-fine particles: gamma- AlO2O3, β-SiC ultra-fine particles of (50 to app. 200 nanometers) were made by an arc discharge in an argon gas atmosphere using Al and Si electrodes. This process enables the production of high-strength ceramics without a binder.

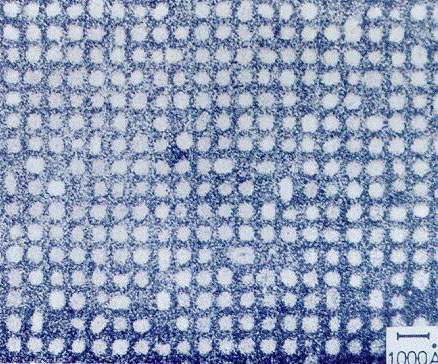

Lattice-shape deposition of ultra-fine particles: A method for depositing gold ultra-fine particles regularly on a silicon substrate with several tens of angstroms spacing was developed, enabling the manufacturing of high-performance electronic elements and for the production of ultra-high density recording materials and ultra-fine beam machining techniques.

Ultra-fine particles of organic compounds: Organic compounds of anthracene, pyrene and phai-locyanine could be atomized to ultra-fine particles by evaporation in a gas. Water-insoluable materials which are almost impossible to soak are easily dispersed in water.

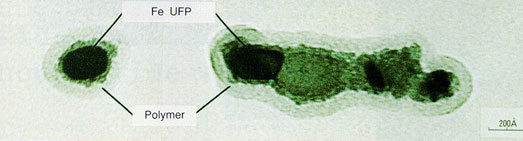

Single molecular ultra-fine particles: Isolated ultra-fine particles such as Ni, Fe, Cu, Sn and Pb could be formed having mean particle diameters of 40 – 200 A. This process will enable the manufacture of new isolated ultra-fine particles coated by polymers which have an affinity to living bodies and are useful for medical and biological applications.

Ultra-fine particle catalysts of higher selectivity: It was found that ultra-fine particles of nickel or copper-zinc compounds are excellent catalysts for the selective hydrogenation of organic compounds.

Polymer-coated ultra-fine particles: Vinyl was introduced to the surface of Fe ultra-fine particles, allowing a polymer coating (5 – 20 nm) to be formed by a radical copolymerization of vinyl monomer and micro-capsules.

Fig 1: Ultra-Fine Spherical Particle of γ-Alumina coated with graphitic carbon.

Fig 2: Arrangement of KC1 UFP as square lattice.

Fig 3: Electron microgragh of encapsulated Fe UFP.